DYLB, DYLK vertical long shaft pump

Classification:

Pump

Hotline:

Product Introduction

DYLK and DYLB vertical long shaft pumps are suitable for power plants, steel mills, water supply companies, sewage treatment plants, petrochemical industries, mining enterprises, as well as municipal water supply and drainage projects, agricultural irrigation, flood control and drainage projects. They can be used to transport clean water, rainwater, pit water, sewage, and seawater at temperatures below 55°C, with a flow range of 30-70000m³/h and a head range of 7-200m. Specially designed for transporting media with temperatures up to 90°C.

Product Features

● Stable operation, safe and reliable, no vacuum start required, long service life.

● Compact pump size with a small footprint; pump length below the foundation can be adjusted for strong adaptability.

● Simple and reliable flow path, saving investment in pump house infrastructure.

● Reasonable structure, easy assembly and disassembly, simple maintenance.

● High pump efficiency reduces operating costs.

Model Description

| 1400DYLK—30Ⅰ |

500DYLB—55.3Ⅰ(×2、3) |

| 1400——Pump outlet diameter 1400mm |

500——Pump outlet diameter 500mm |

| L———Vertical long shaft pump |

L———Vertical long shaft pump |

| K———Rotor can be extracted |

B———Rotor cannot be extracted |

| 30———Design head of the pump |

55.3———Design head of the pump |

| Ⅰ———Pump design sequence (no marking for first design) |

Ⅰ———Pump design sequence (no marking for first design) |

| Note: For large diameter pumps, multi-stage designs are generally not adopted. |

×2———Indicates that the pump has two stages. |

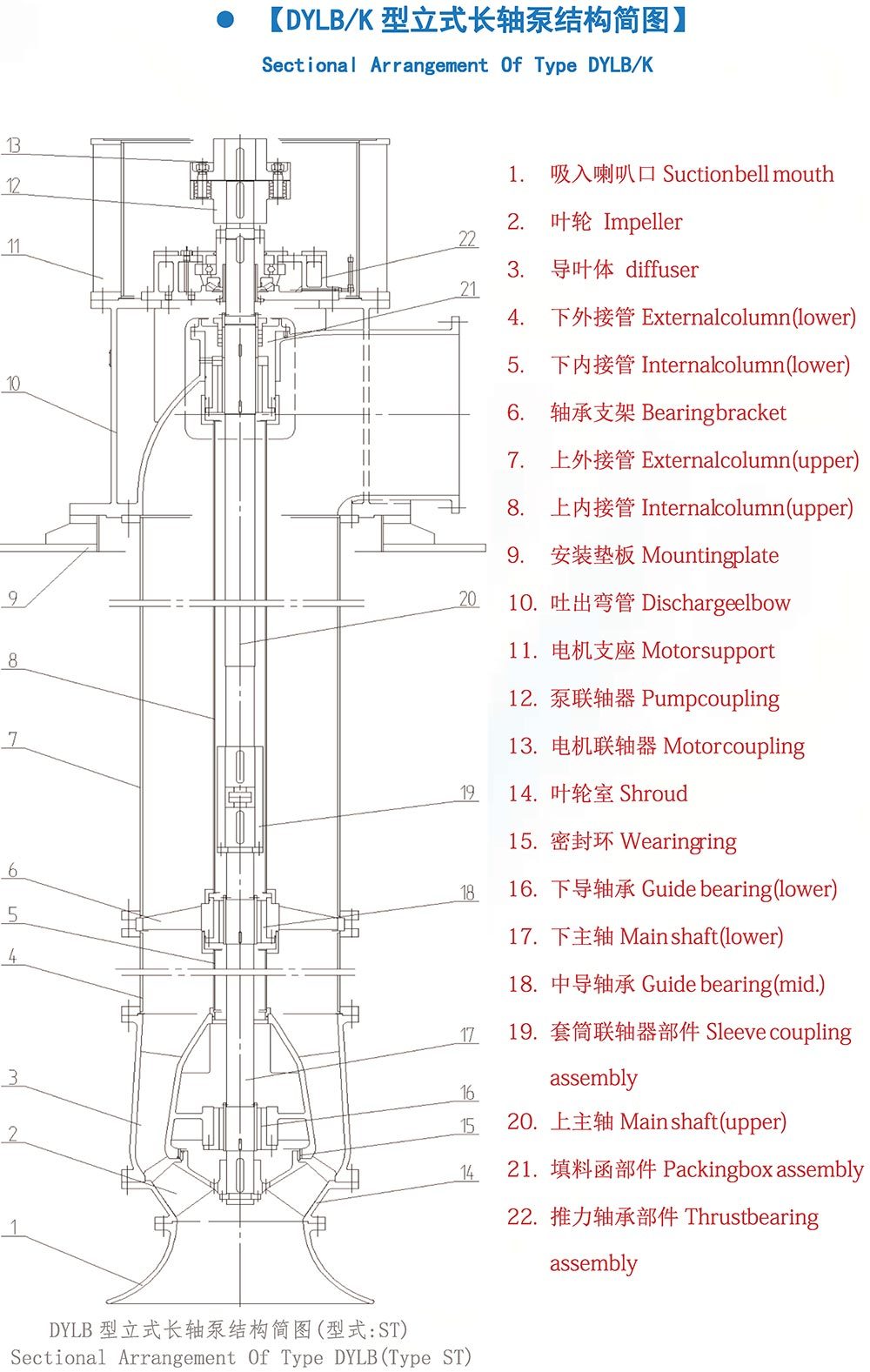

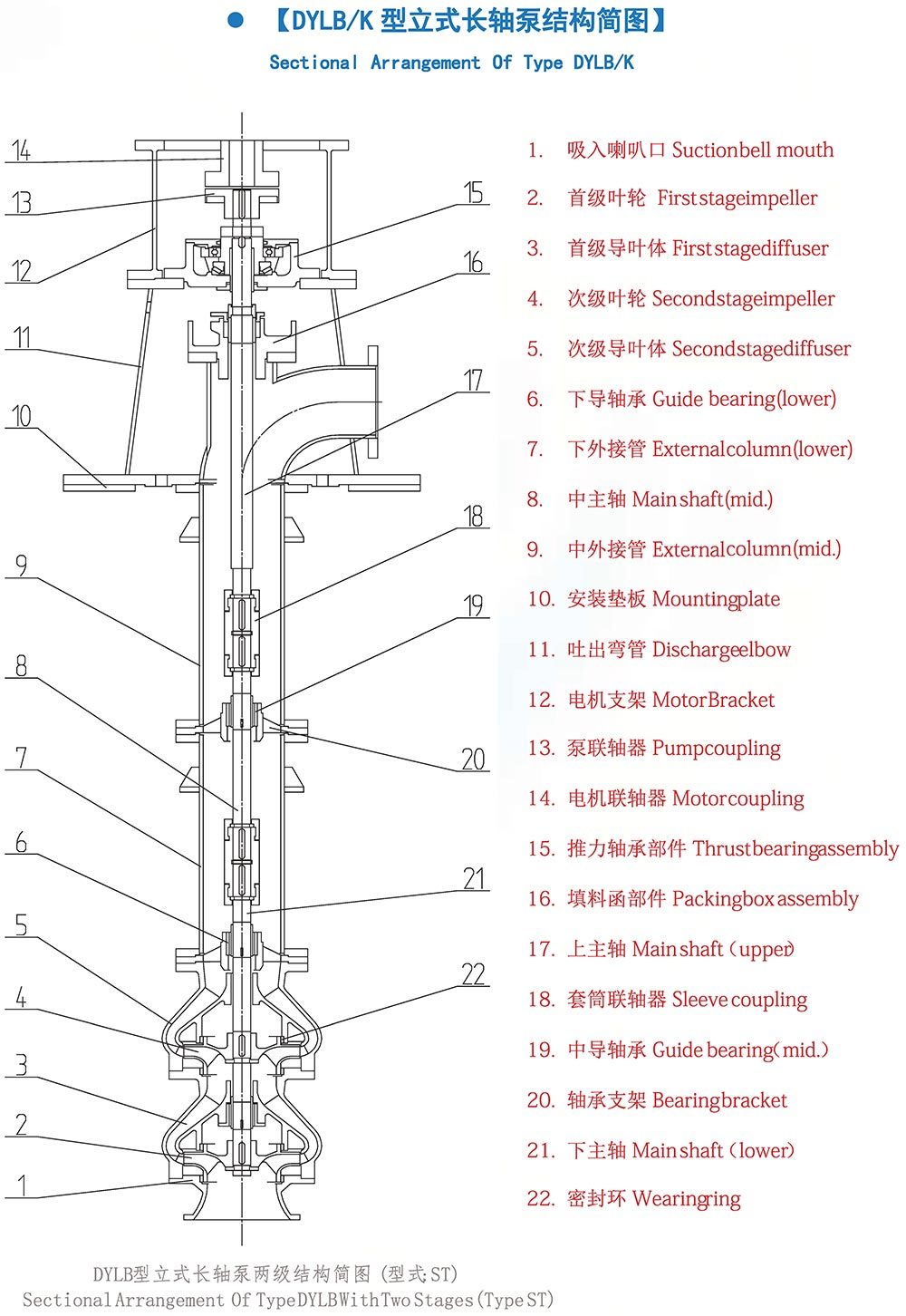

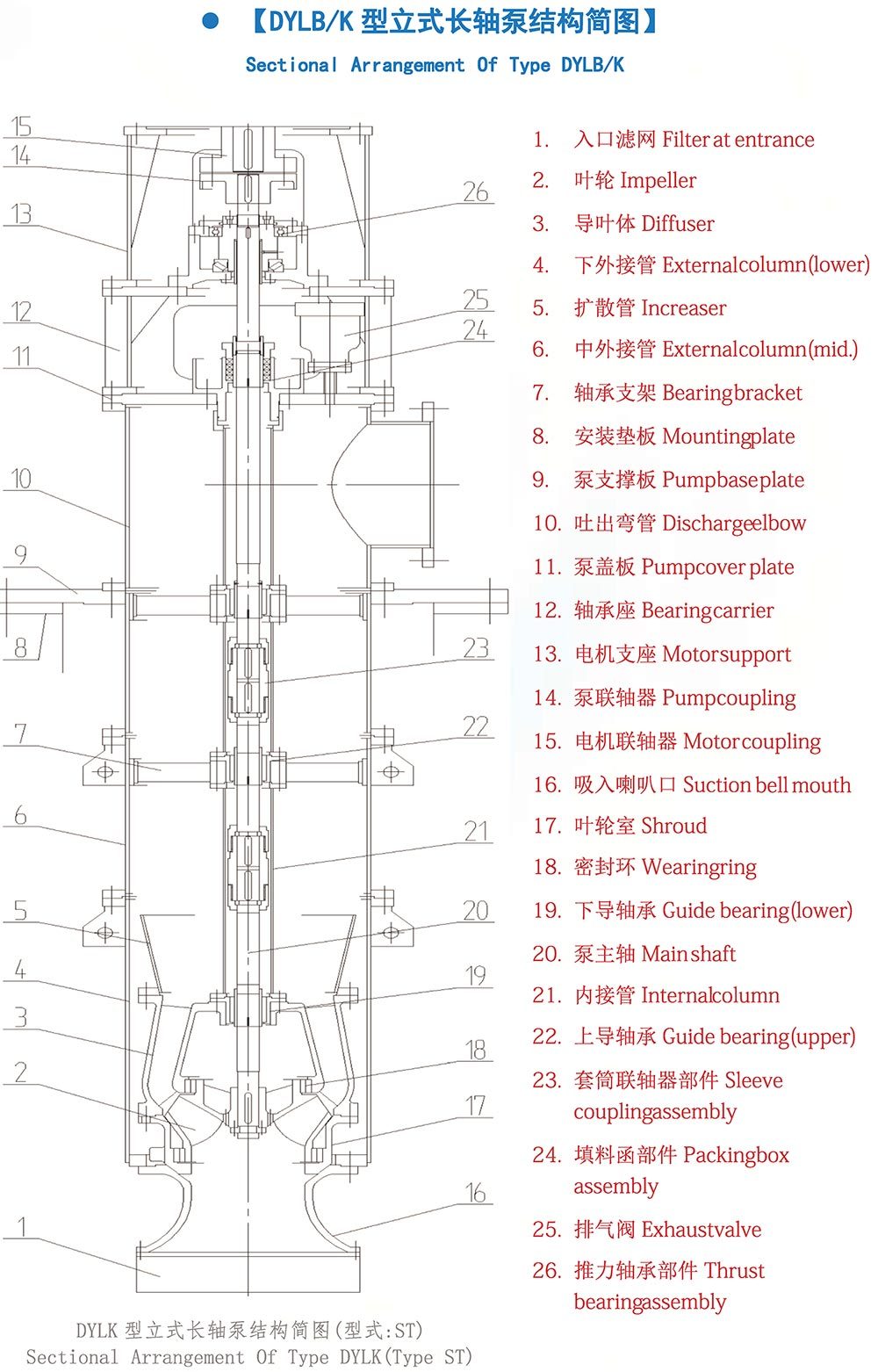

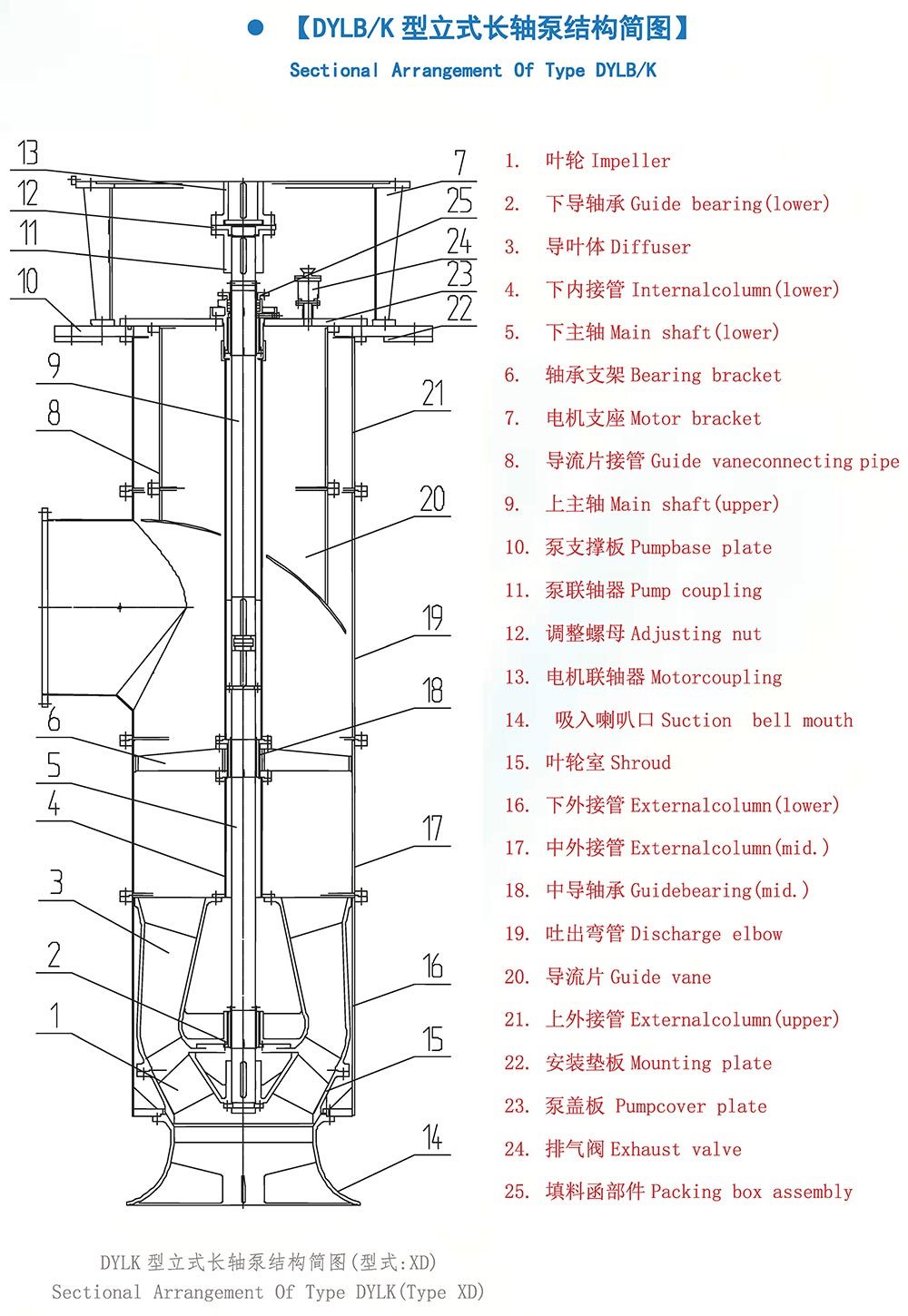

Product Structure Description

DYLK and DYLB pumps are vertical single-stage (multi-stage) centrifugal or mixed flow pumps with guide vanes.

The structural types of the pump include those with the pump outlet above or below the installation foundation (designated as S and X respectively), those bearing axial forces on the pump or motor (designated as T and D respectively), and those with external lubrication water or self-lubricating pumps.

The installation types of the pump include wet pit installation or dry pit installation.

Wet pit installation: The lower part of the pump is submerged in the suction pool.

Dry pit installation: The pump uses pipeline water intake; a 90° elbow pipe connects between the suction bellmouth and the inlet pipeline.

The pump bearings are rubber guide bearings or sail bearings.

When the pump diameter is below 1000mm, the rotor is generally non-extractable; axial water thrust and rotor weight are generally borne by thrust bearings in the pump body; an elastic coupling is used between the pump and motor; the pump outlet is located above the installation surface foundation (designated as ST). If required, it can also be designed to have the motor bear axial water thrust and rotor weight; or other combinations of structural forms (designated as SD, XT, XD); if users have requirements, it can also be designed as an extractable structure. When the pump diameter is above 1000mm, the rotor is generally extractable; axial water thrust and rotor weight are generally borne by thrust bearings in the motor; a rigid coupling is used between the pump and motor; the pump outlet is located below the installation surface foundation (designated as XD). If required, it can also be designed to have the pump bear axial water thrust and rotor weight; or other combinations of structural forms (designated as XT, SD, ST); if users have requirements, it can also be designed as a non-extractable structure.

When the pump body bears axial water thrust and rotor weight, the thrust bearing uses thin oil lubrication; thrust bearing components are equipped with Pt100 temperature measuring elements to measure bearing temperature or pressure thermometers to measure lubrication oil temperature.

The axial seal of the pump uses packing seals.

The gap between the impeller and volute (rotating part and stationary part) can be adjusted on the pump installation foundation for convenient operation.

From the discharge direction looking at the pump, the motor junction box and external lubrication water connection pipe are located on the left side. It can also be arranged in other positions according to user requirements.

Main Component Materials

| Media |

清水 |

海水 |

污水(含磨料) |

| 吐出弯管 |

Q235-A |

HT200Ni2Cr |

Q235-A |

| 导叶、吸入喇叭口 |

HT200 |

HT200Ni2Cr |

HT200、QT500-7 |

| 叶轮 |

ZG1Cr13Ni1 HT200 |

ZG0Cr18Ni9 |

QT500-7 |

| 叶轮室、密封环 |

HT200 |

ZG0Cr18Ni9 |

ZG1Cr13Ni1 |

| 主轴 |

45、2Cr13 |

2Cr13、0Cr18Ni9 |

45、2Cr13 |

| Shaft sleeve |

45,2Cr13 |

2Cr13、0Cr18Ni9 |

2Cr13, 1Cr18Ni9 |

| Guide bearing |

HT200+abrasive rubber |

HT200+abrasive rubber |

HT200+abrasive rubber |

Note: According to the user's specific requirements, other suitable materials can be selected. Cast iron impellers are only suitable for closed impellers.

Structural diagram of DYLB/K type vertical long shaft pump

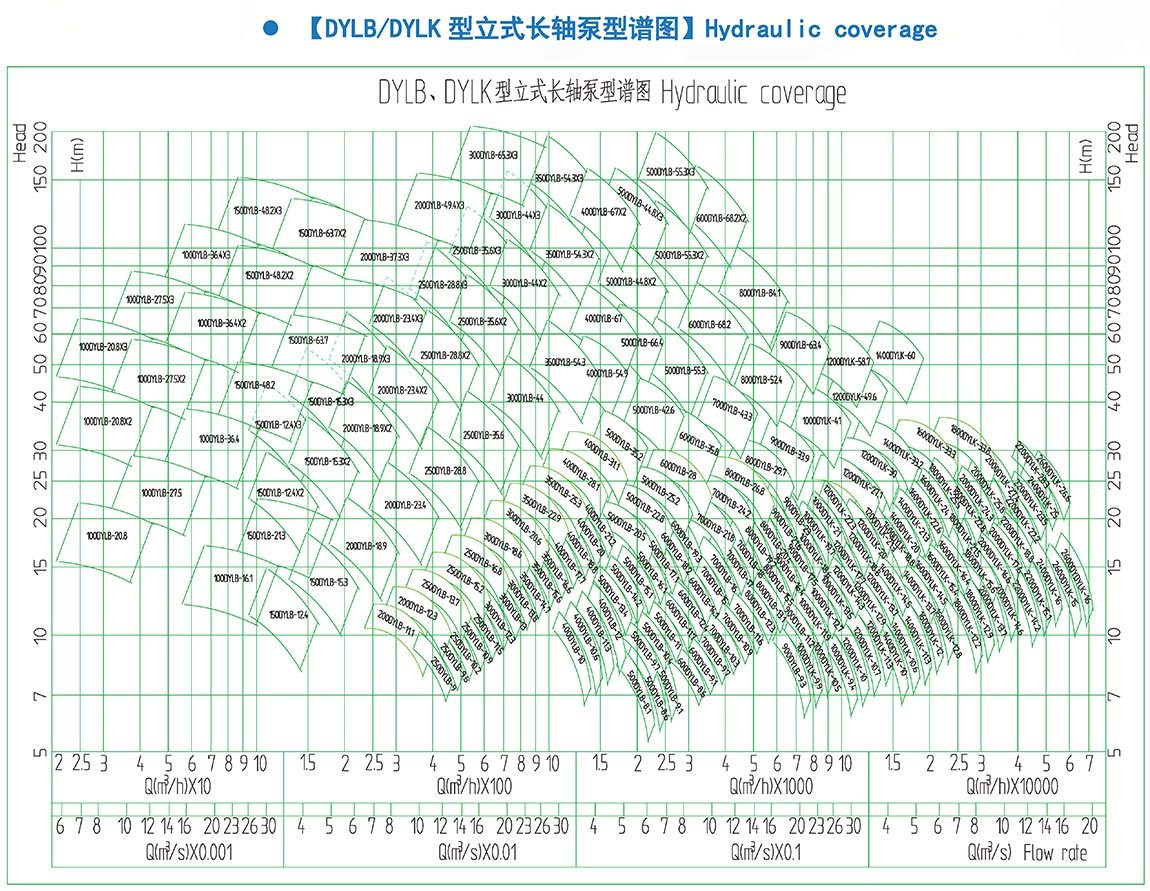

Type spectrum diagram of DYLB/DYLK type vertical long shaft pump

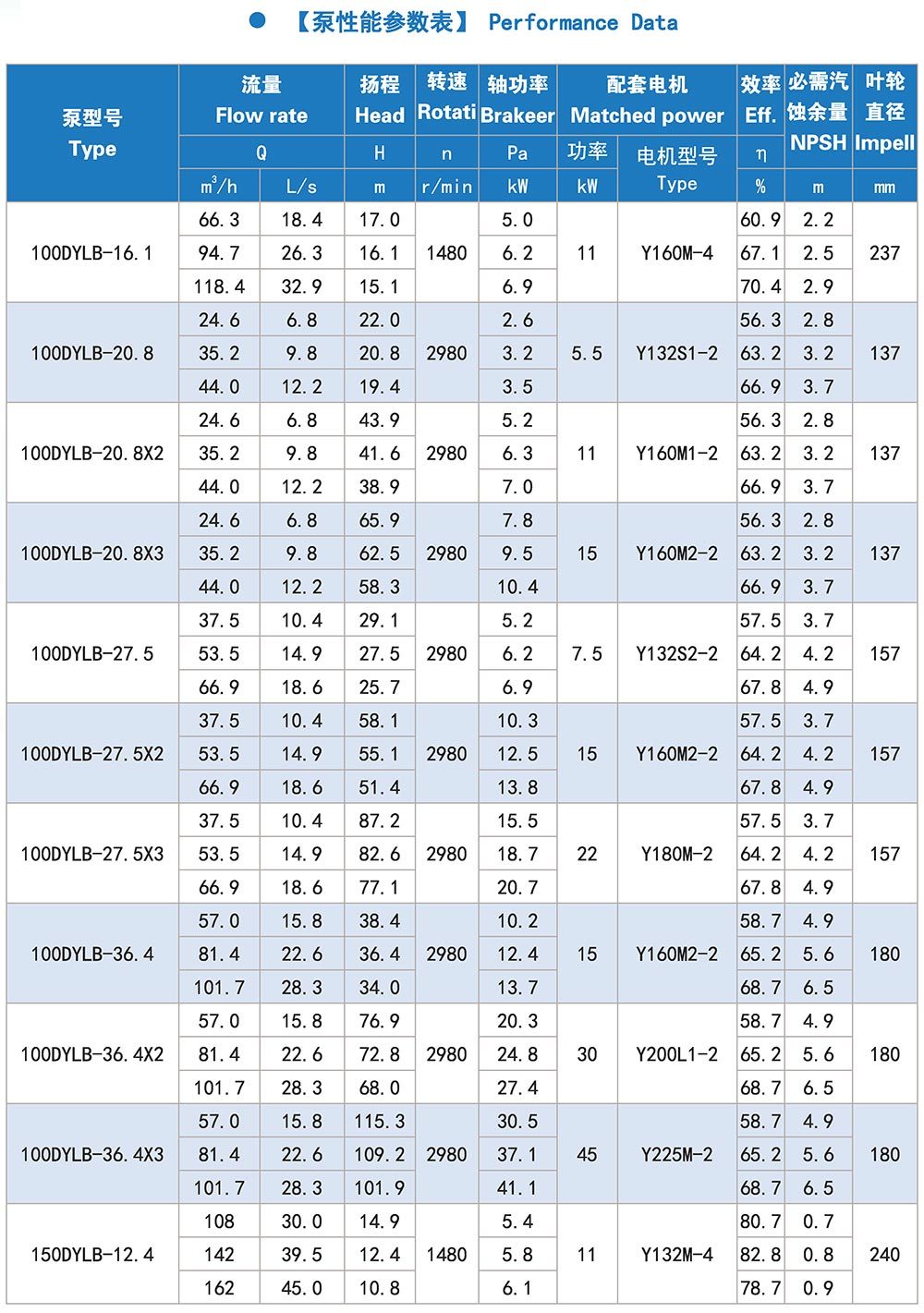

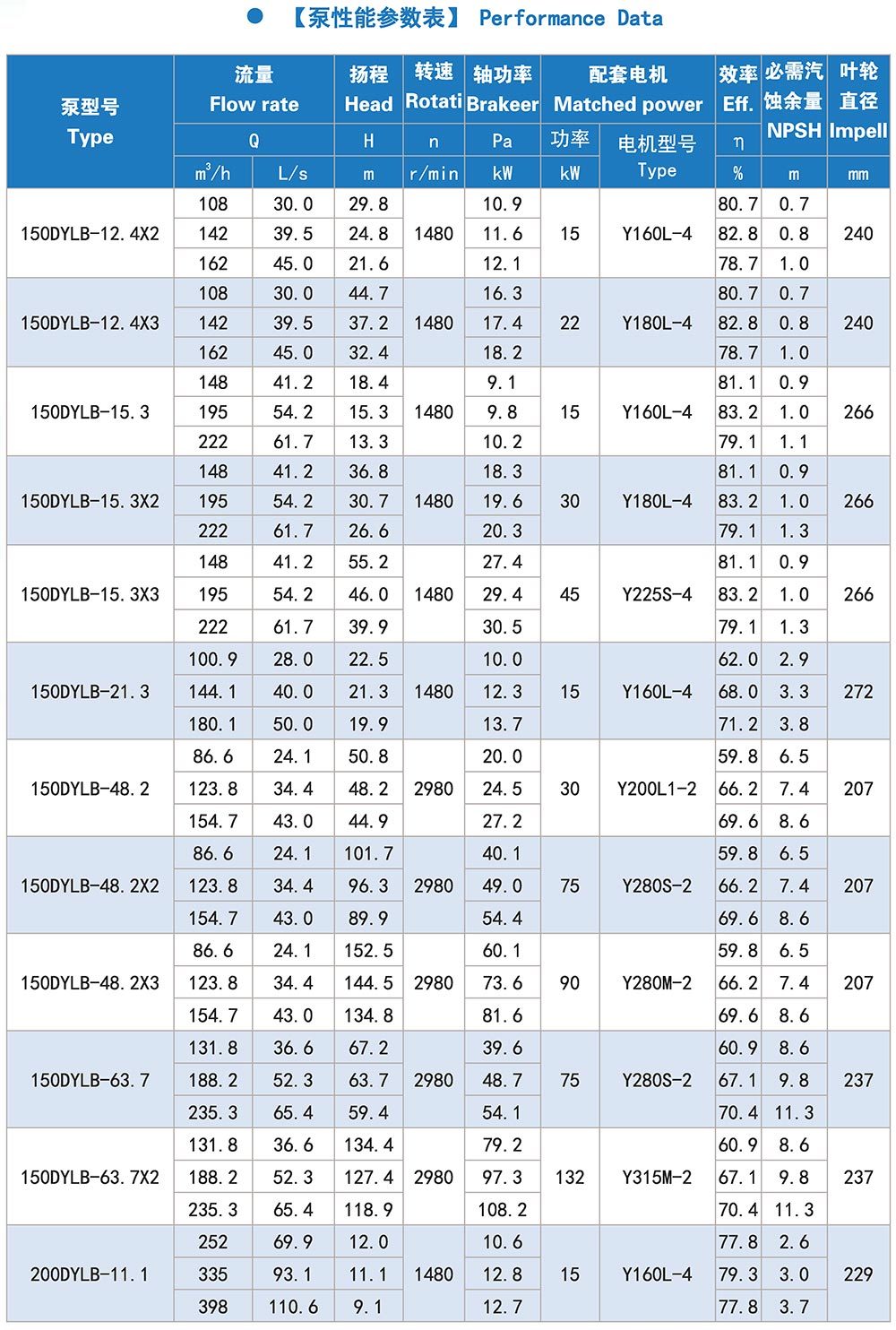

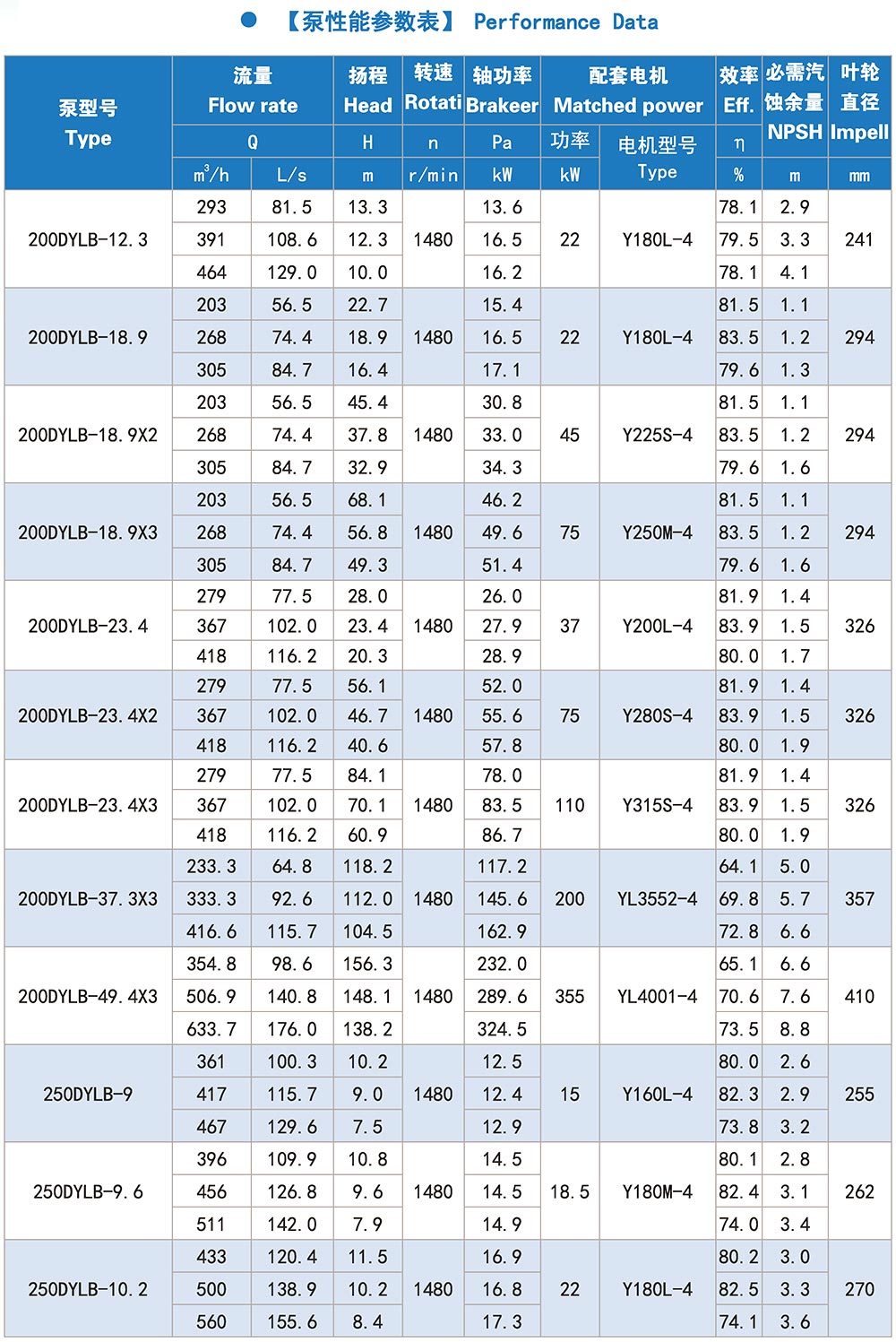

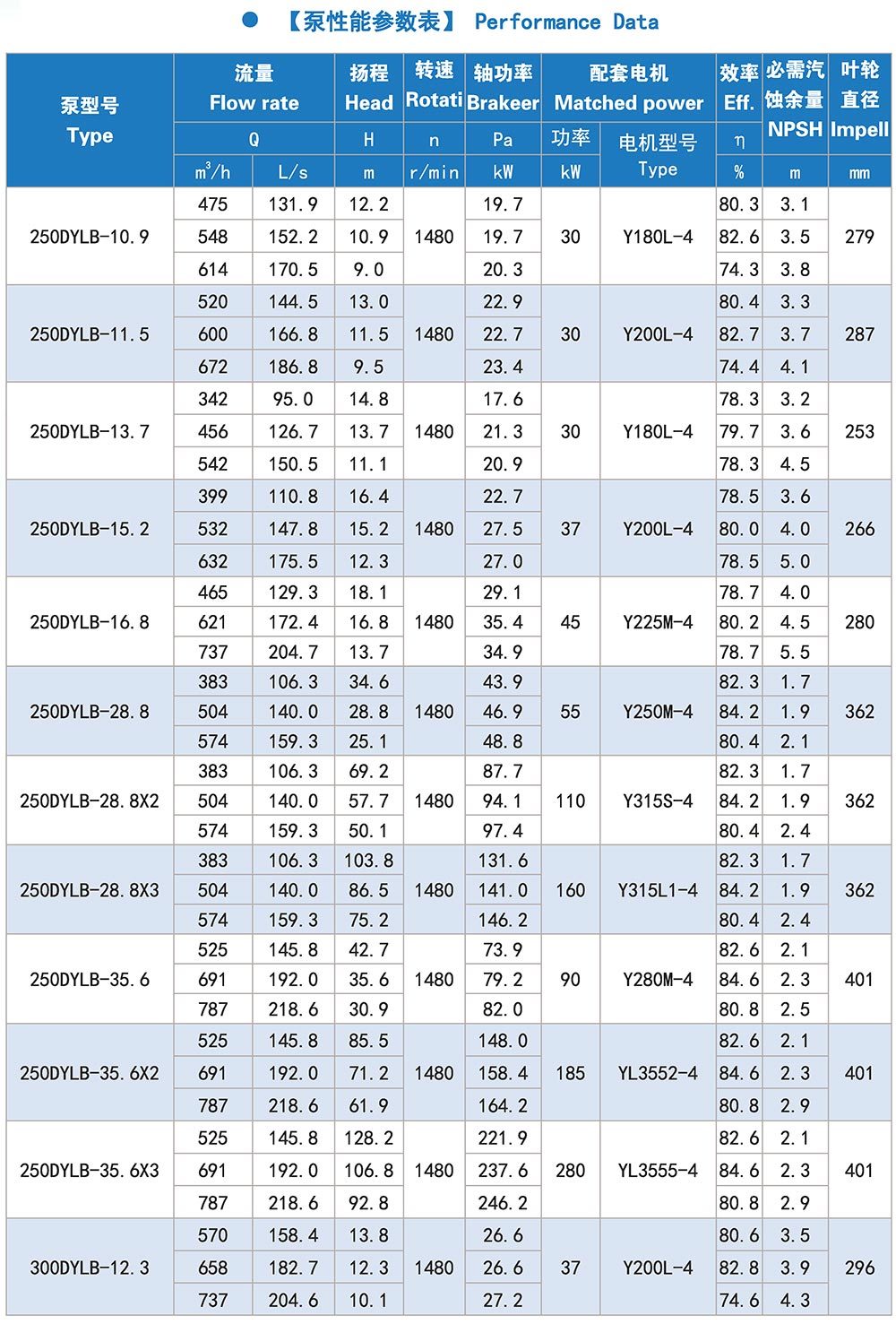

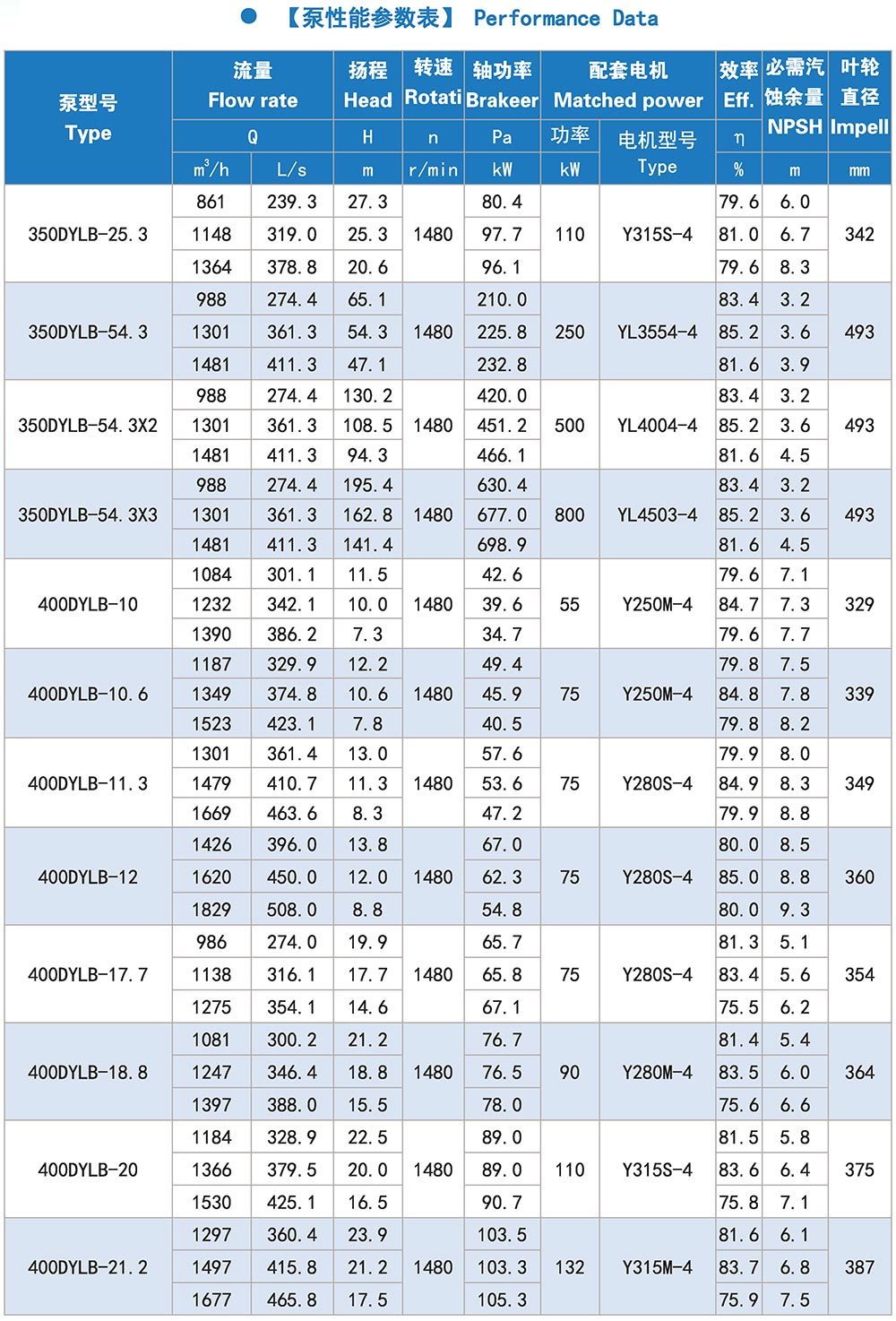

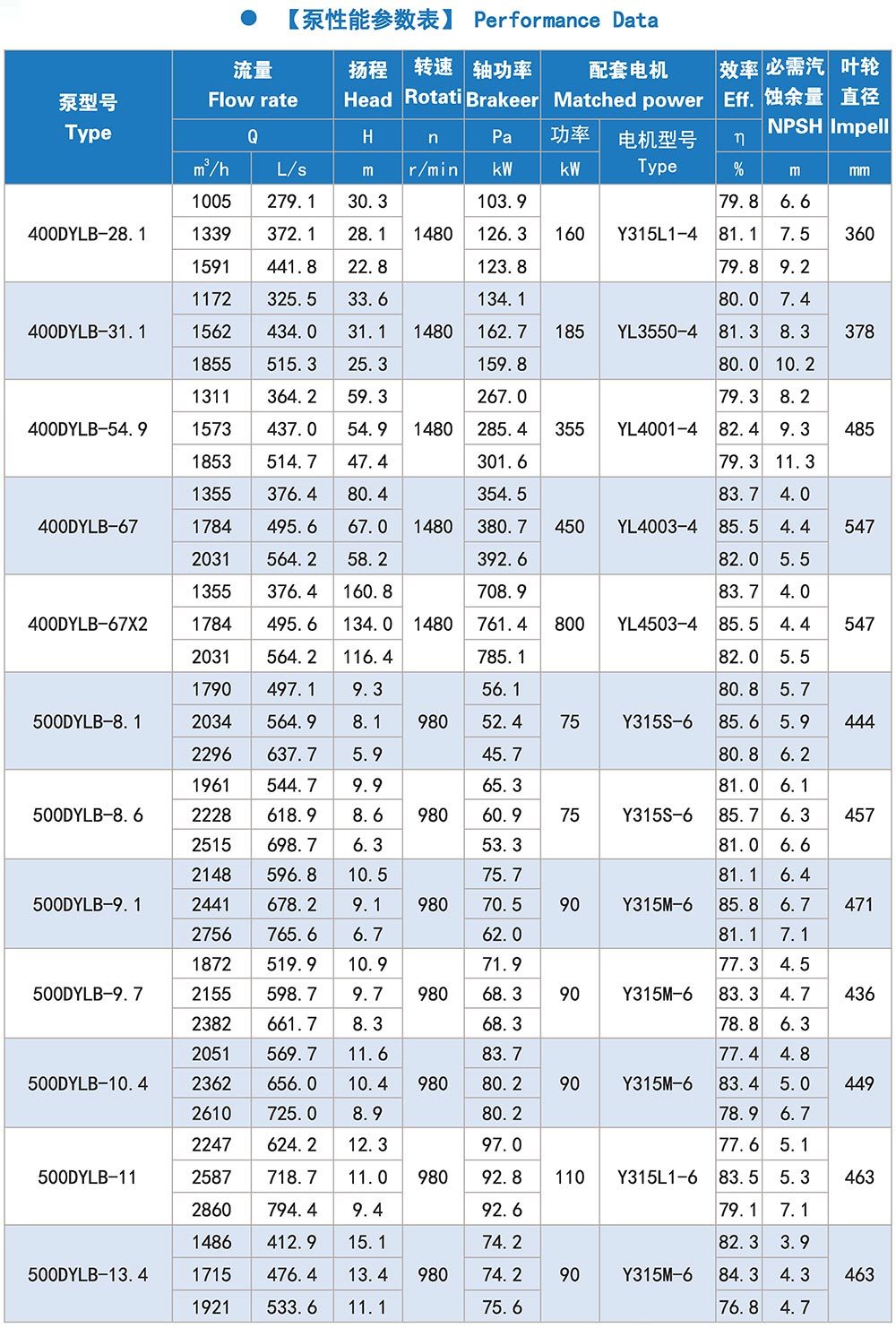

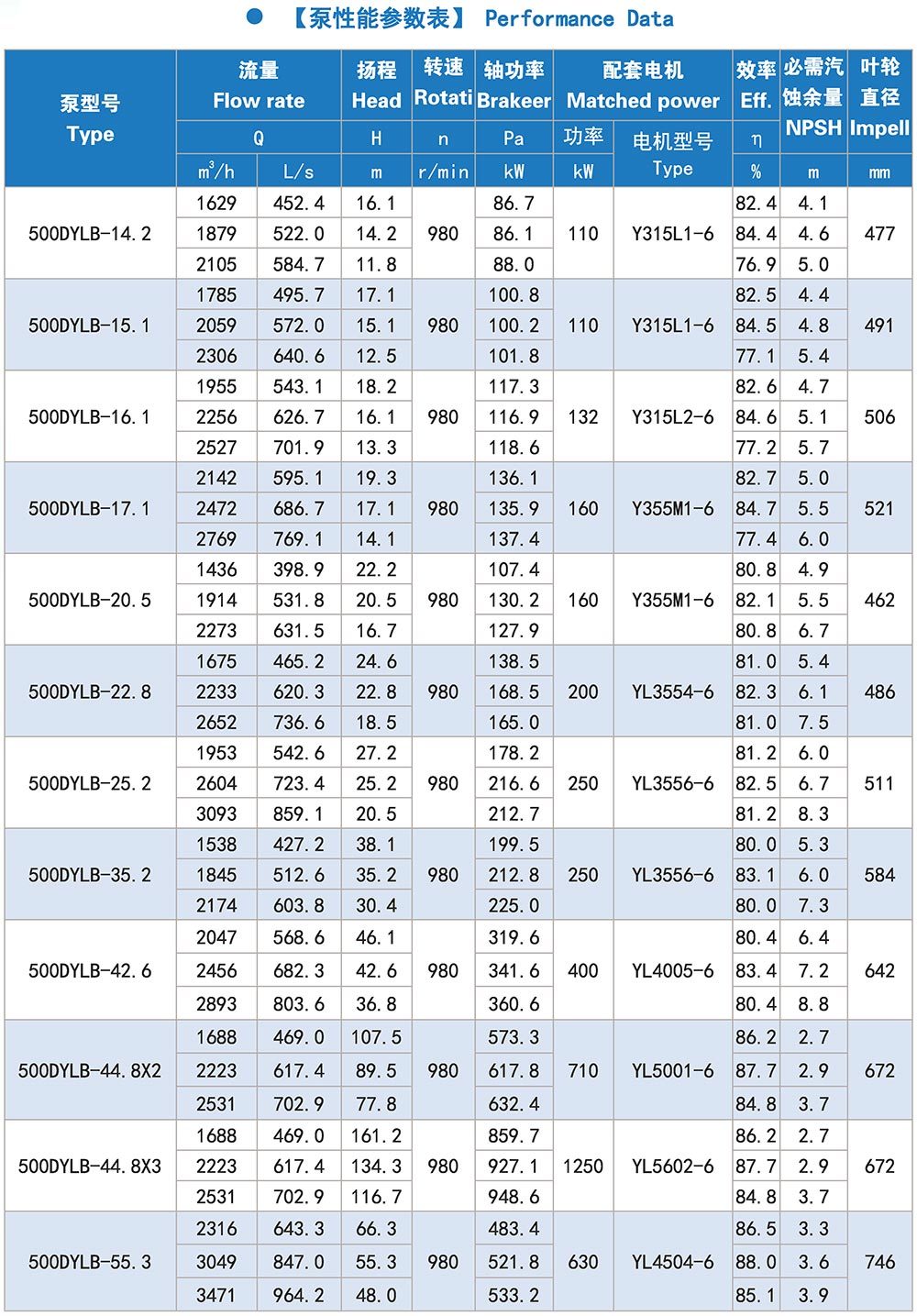

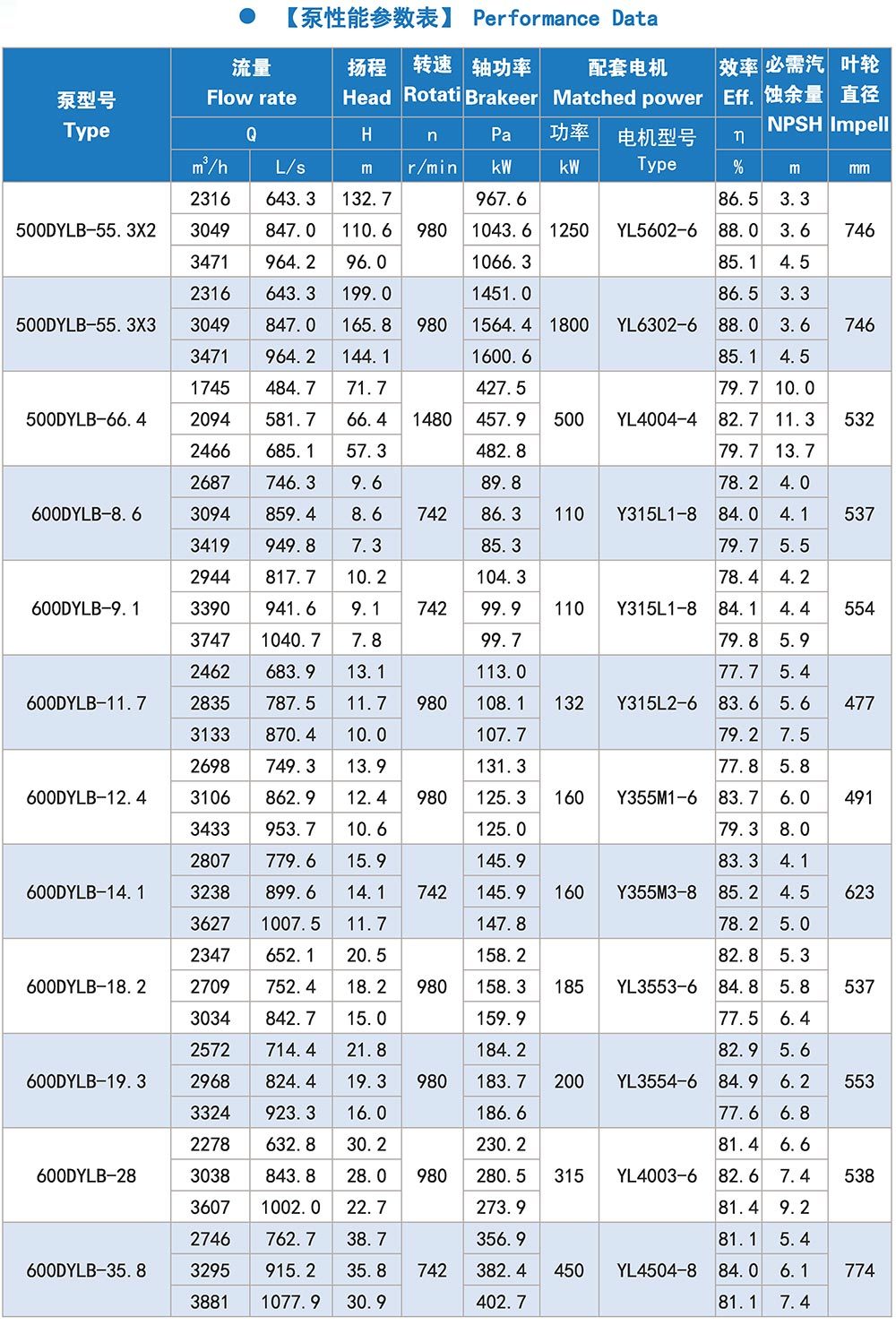

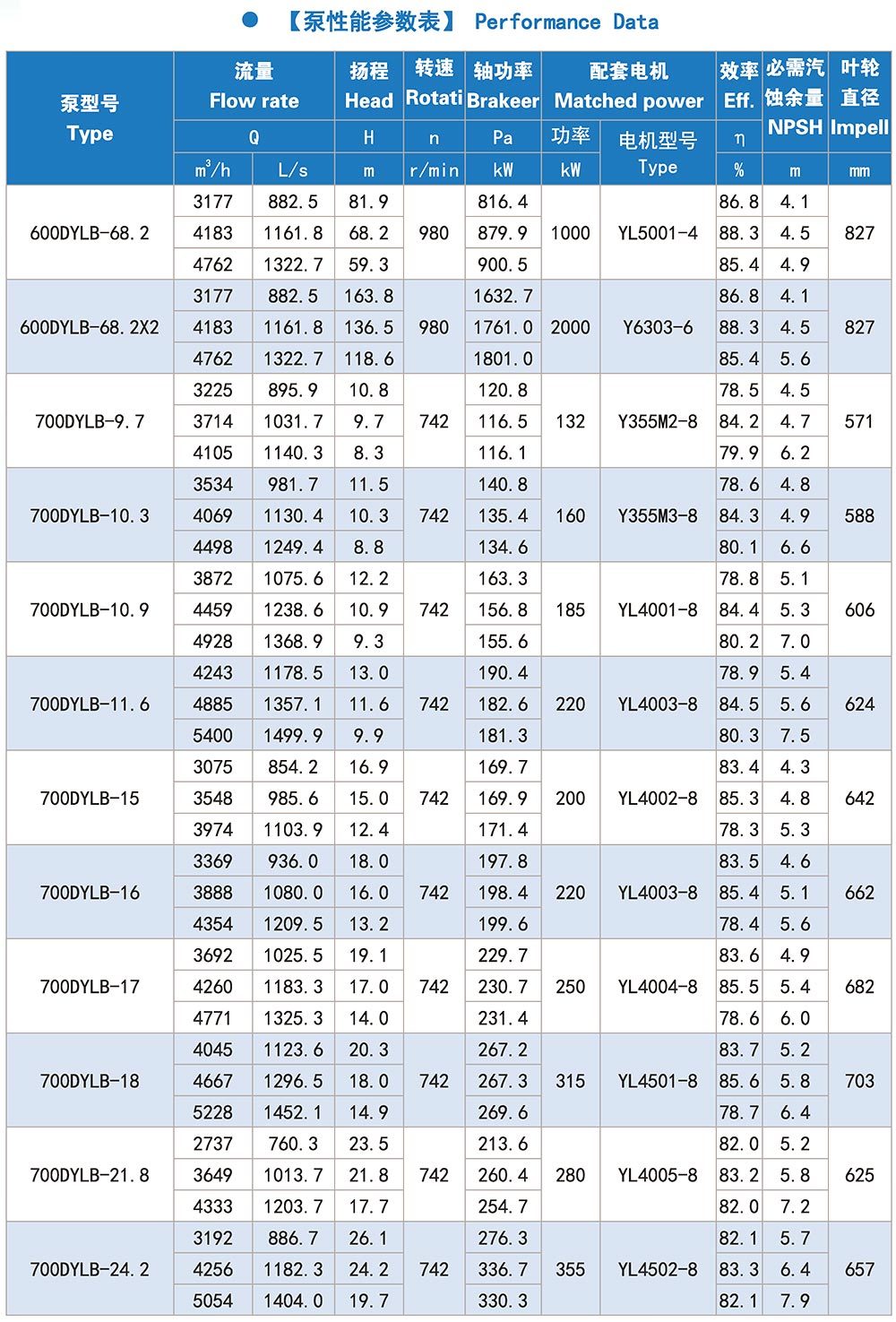

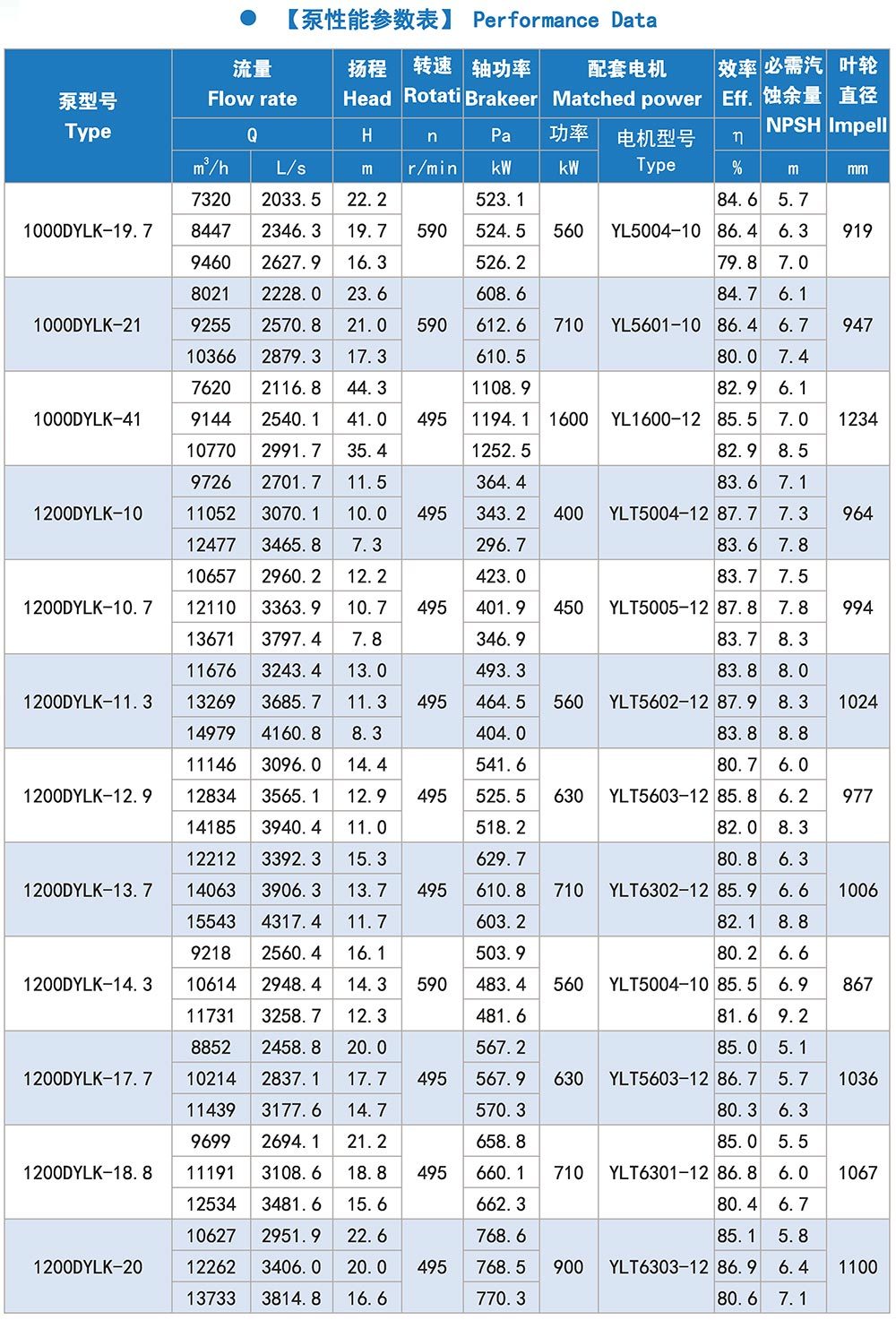

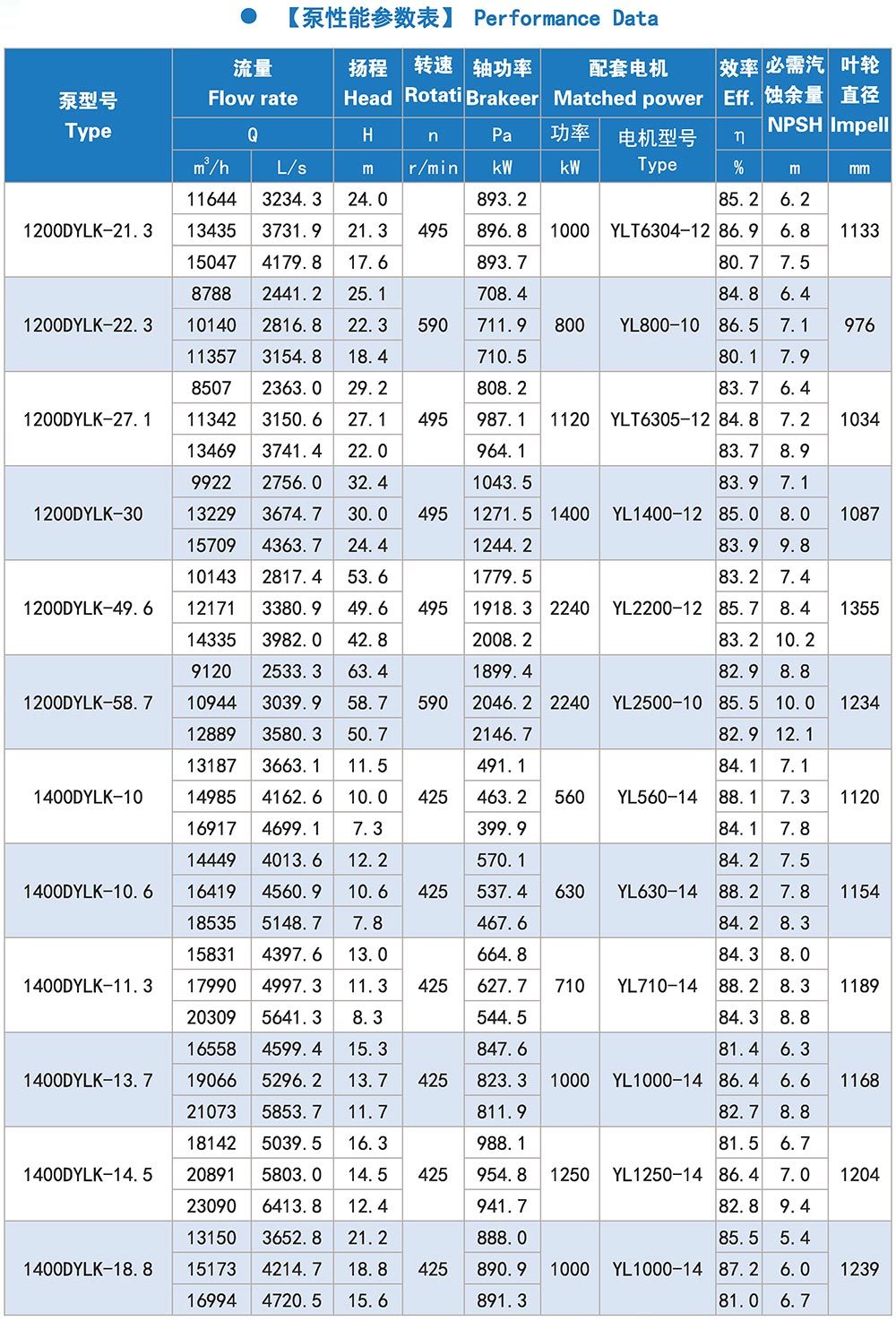

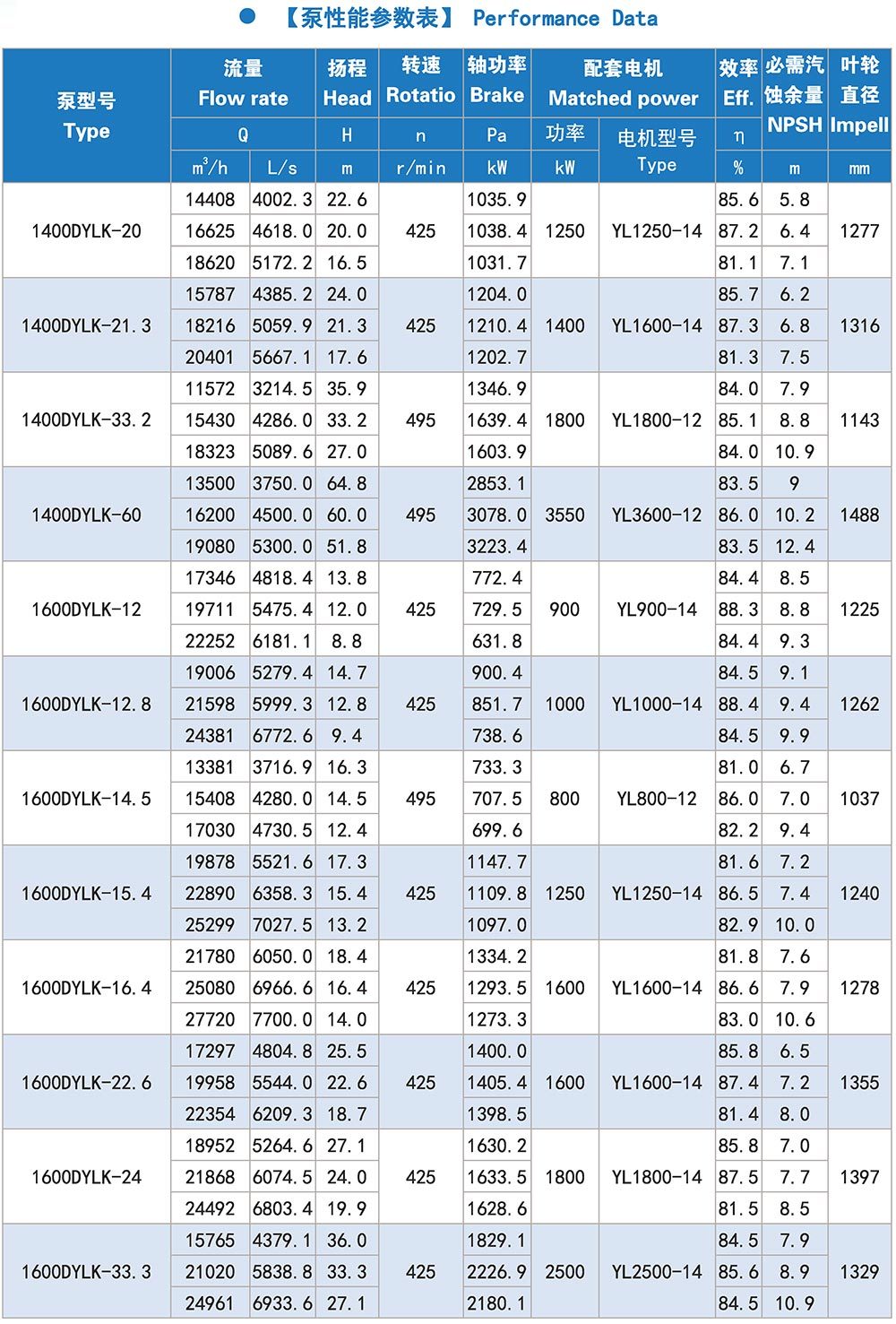

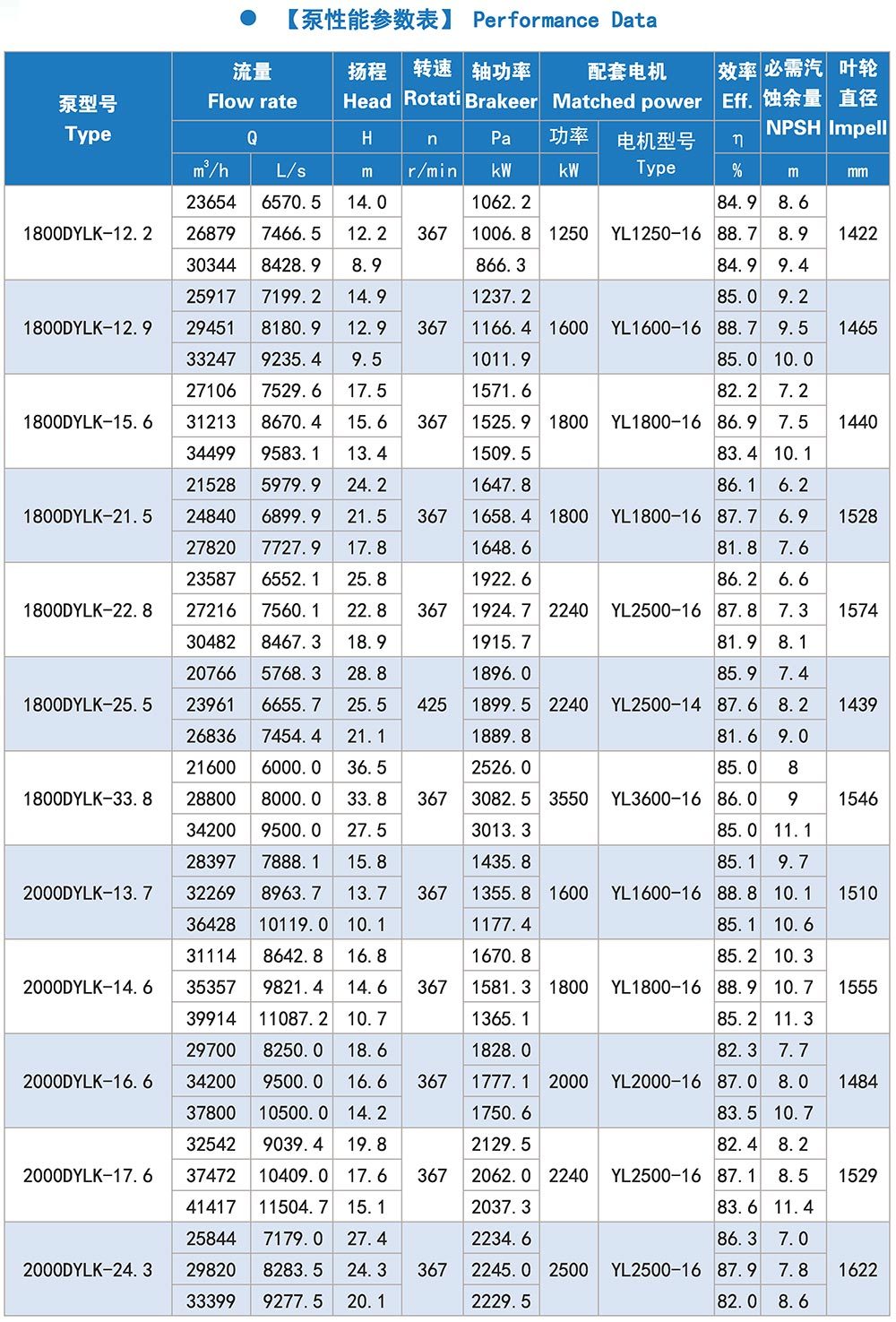

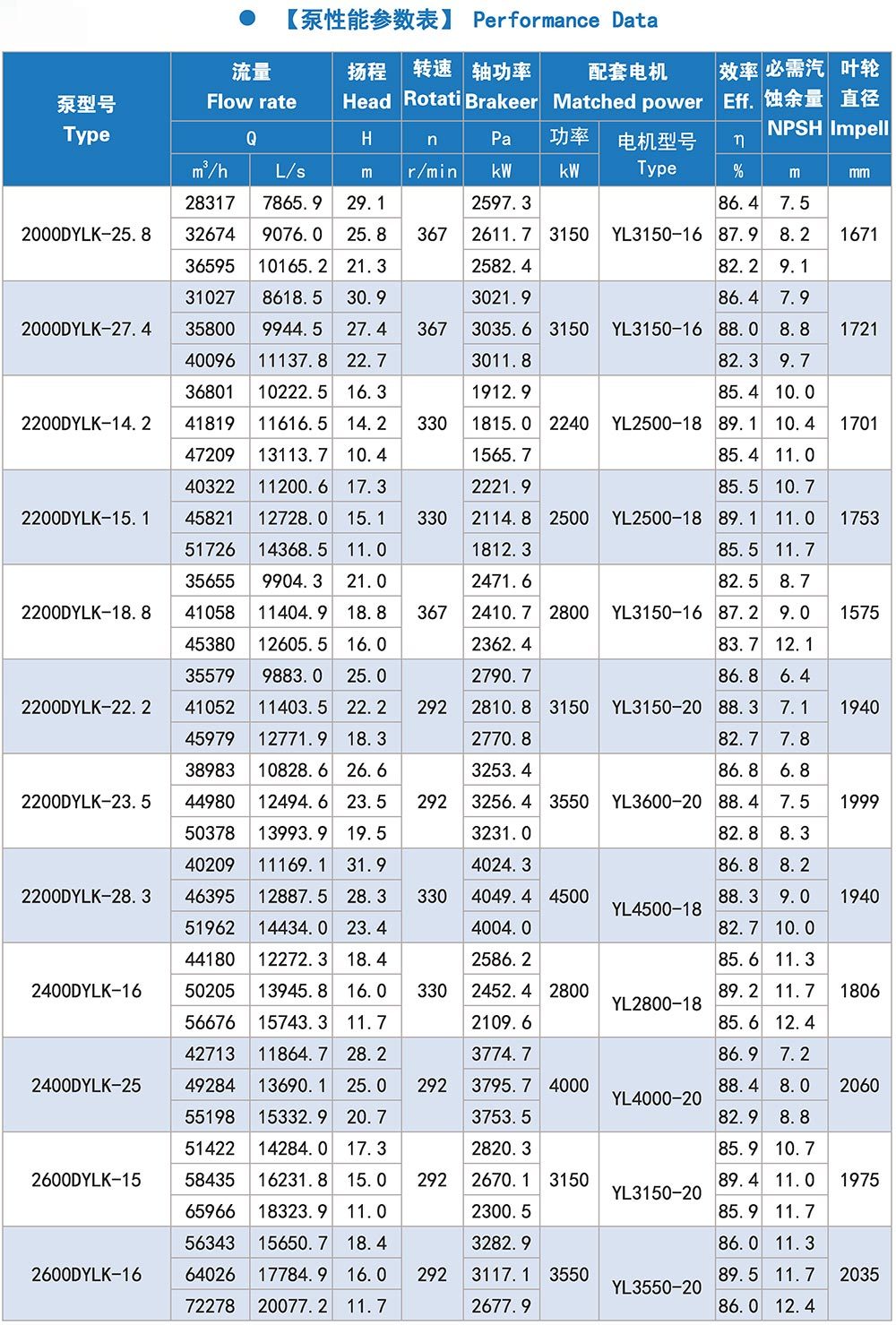

Pump performance parameter table

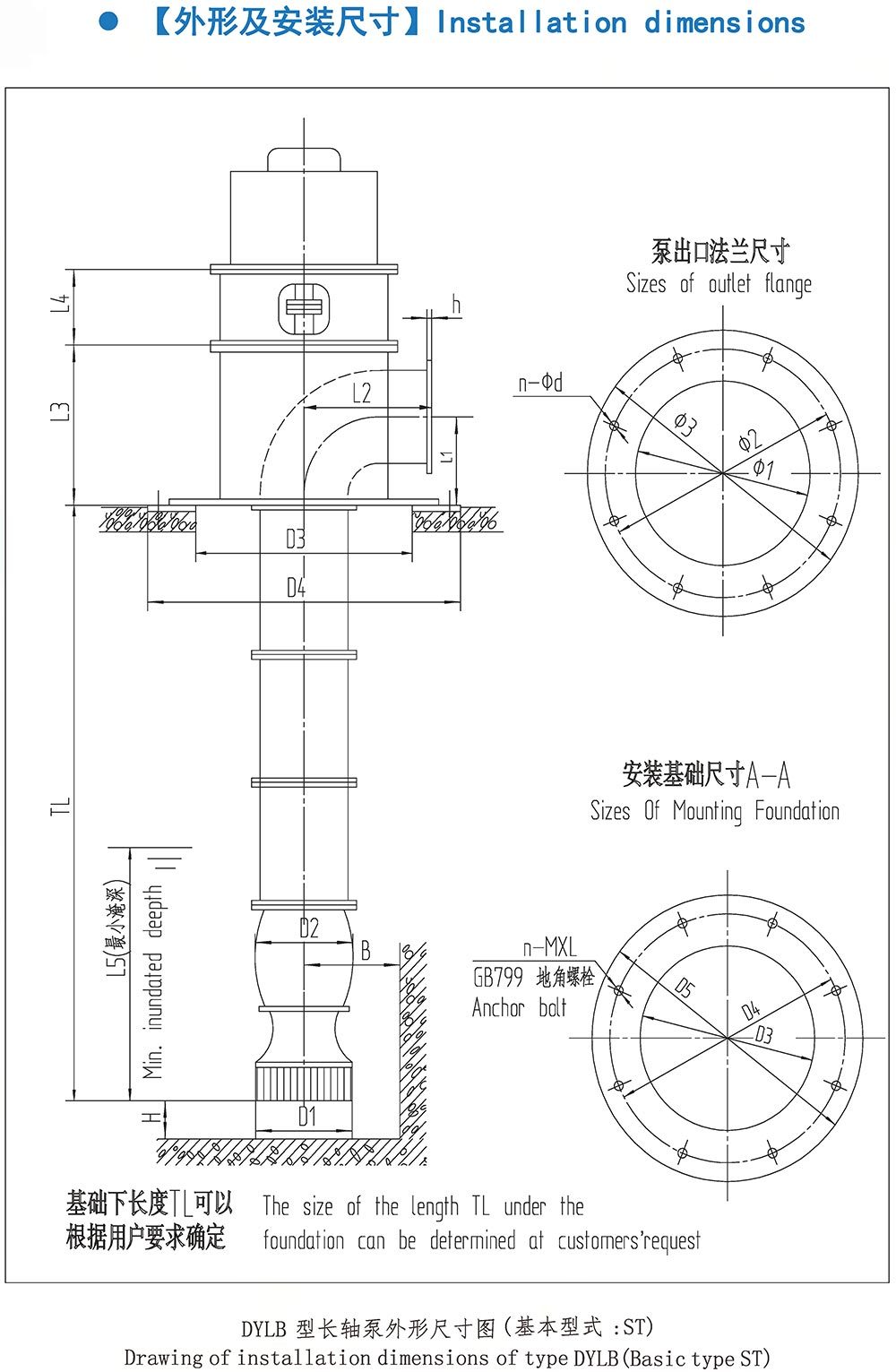

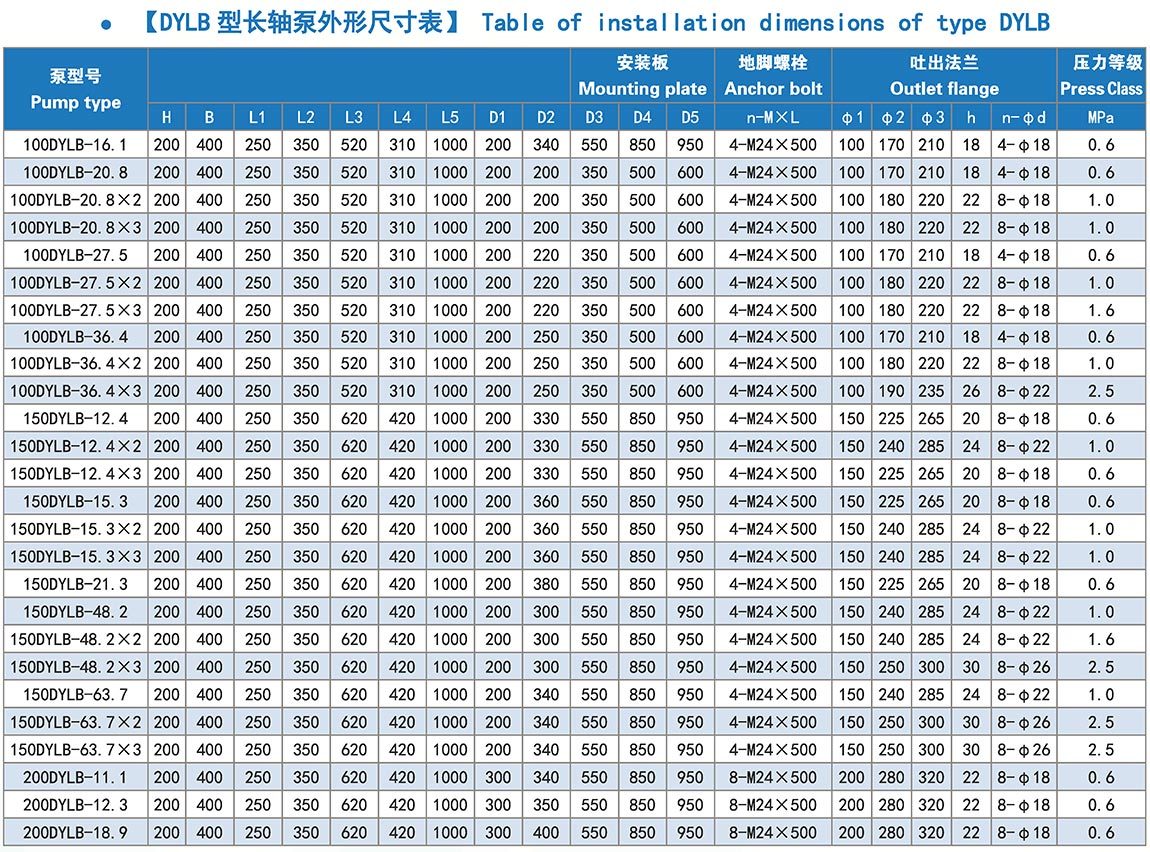

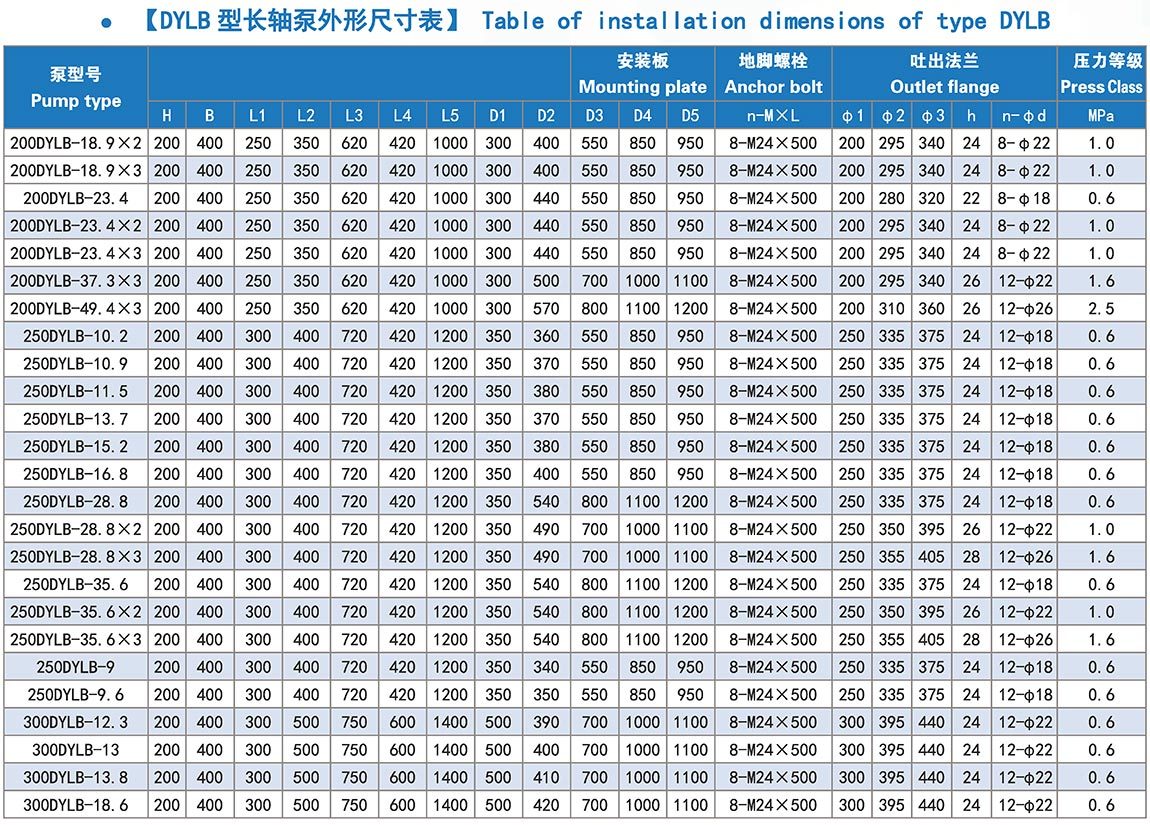

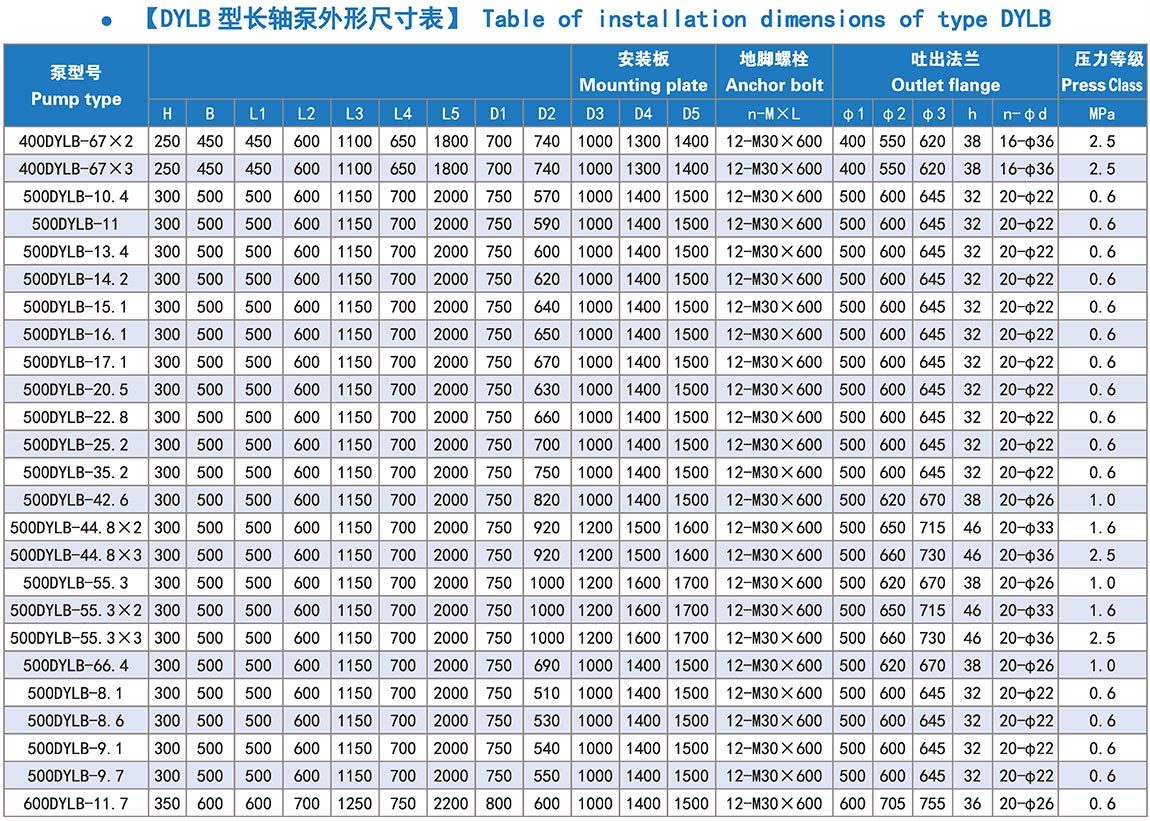

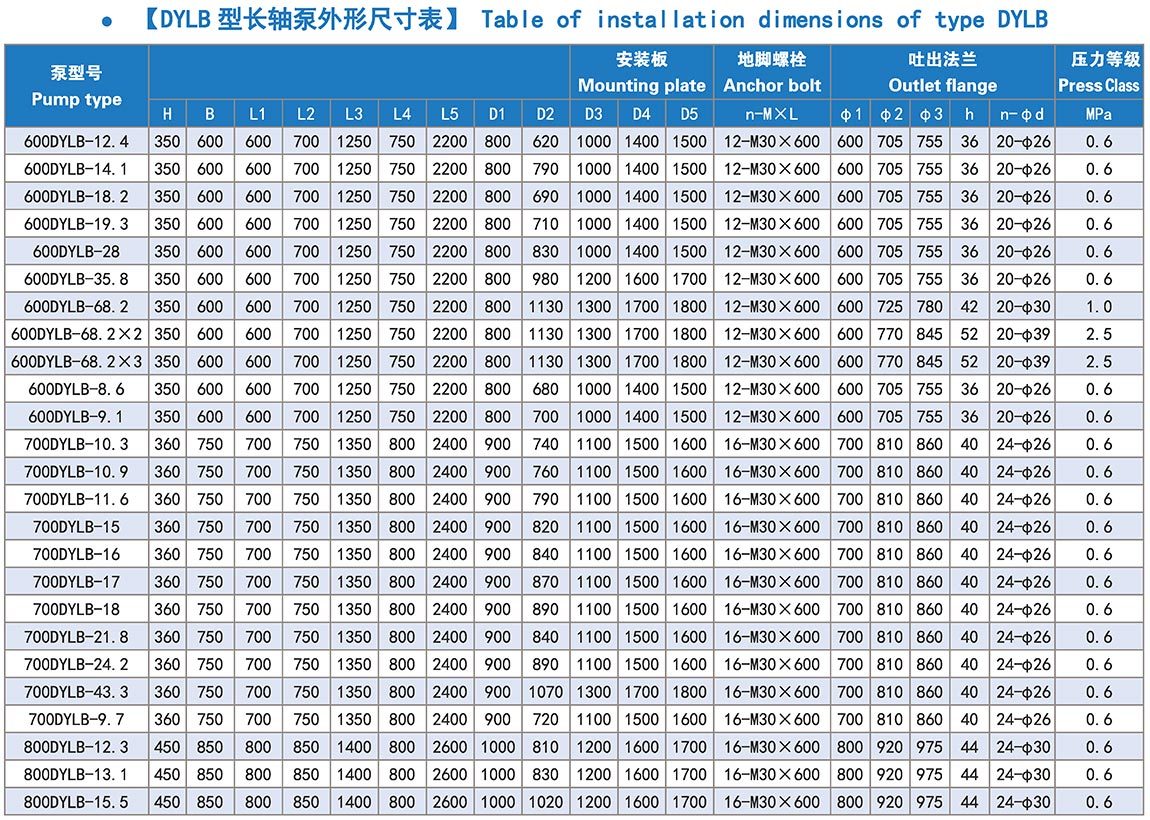

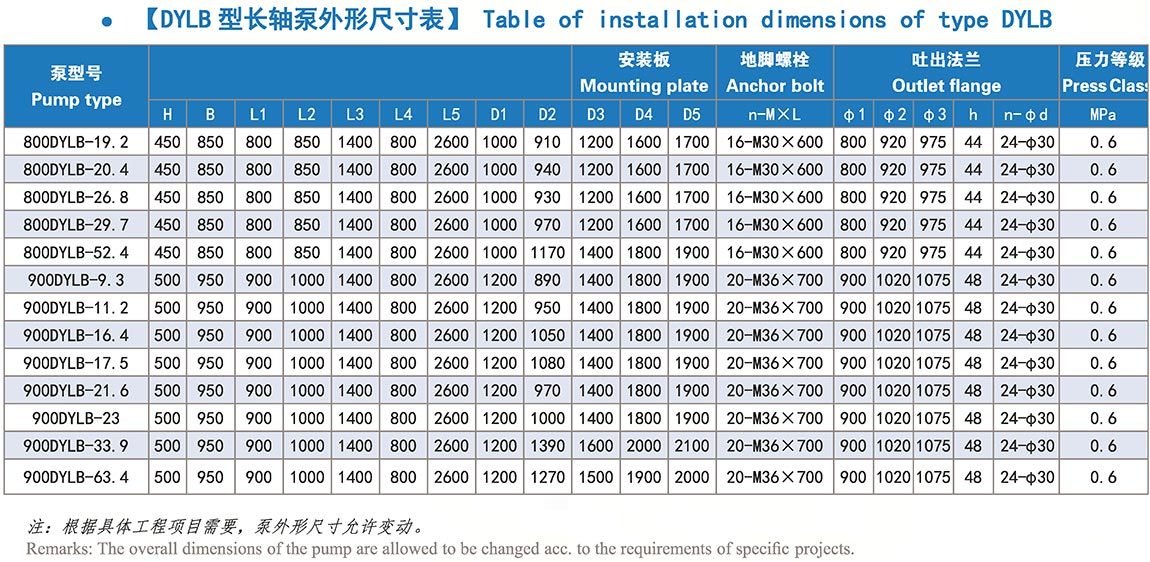

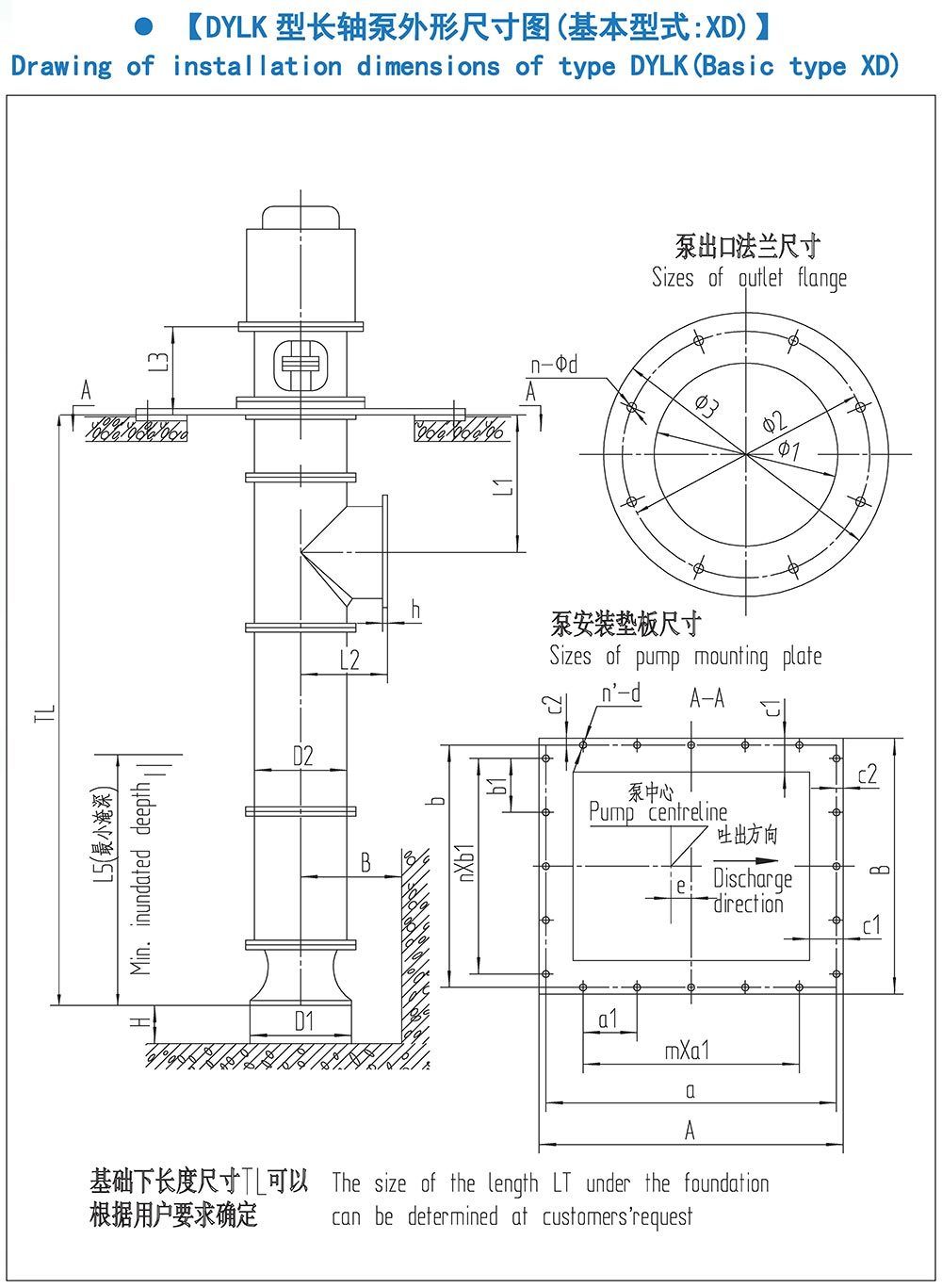

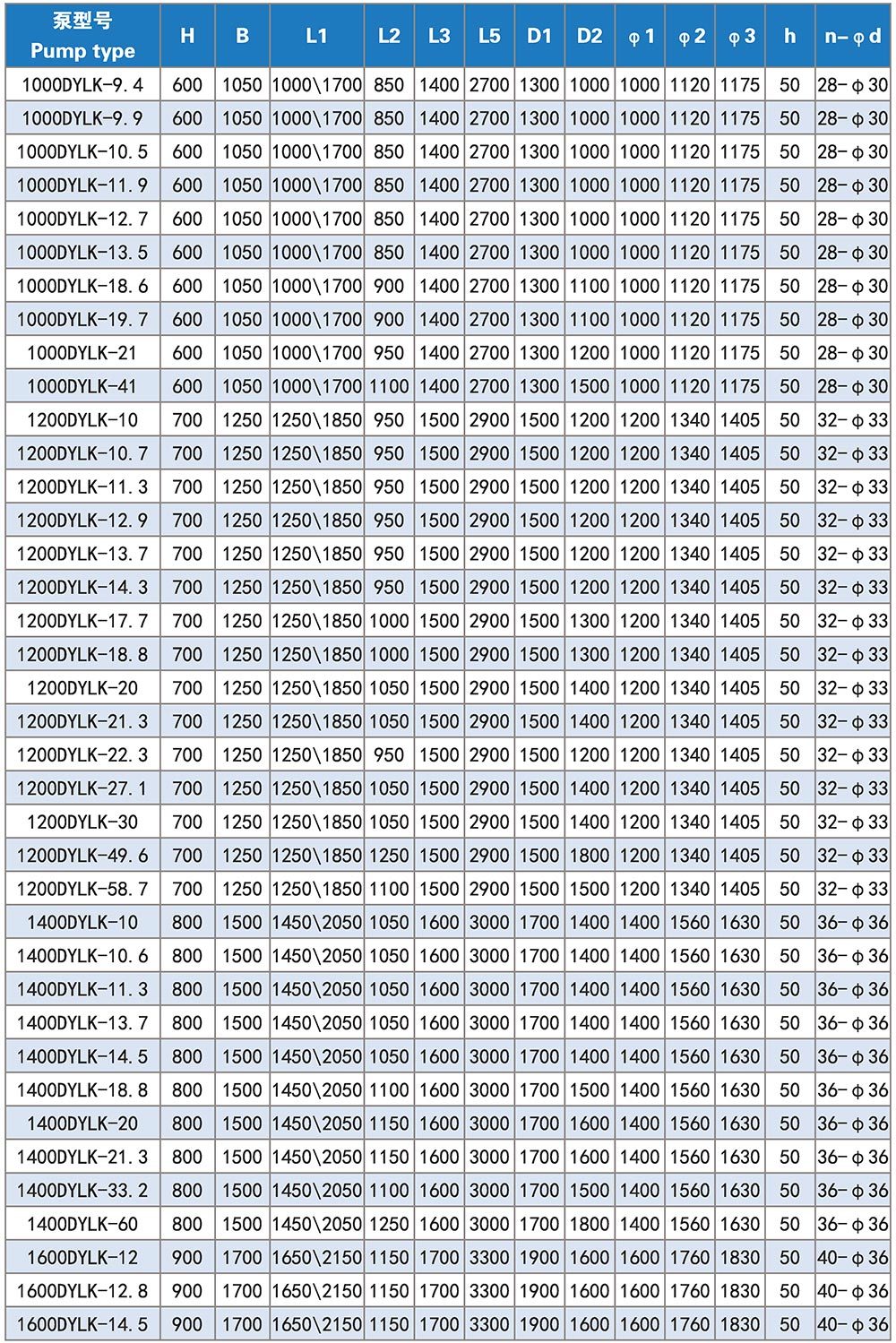

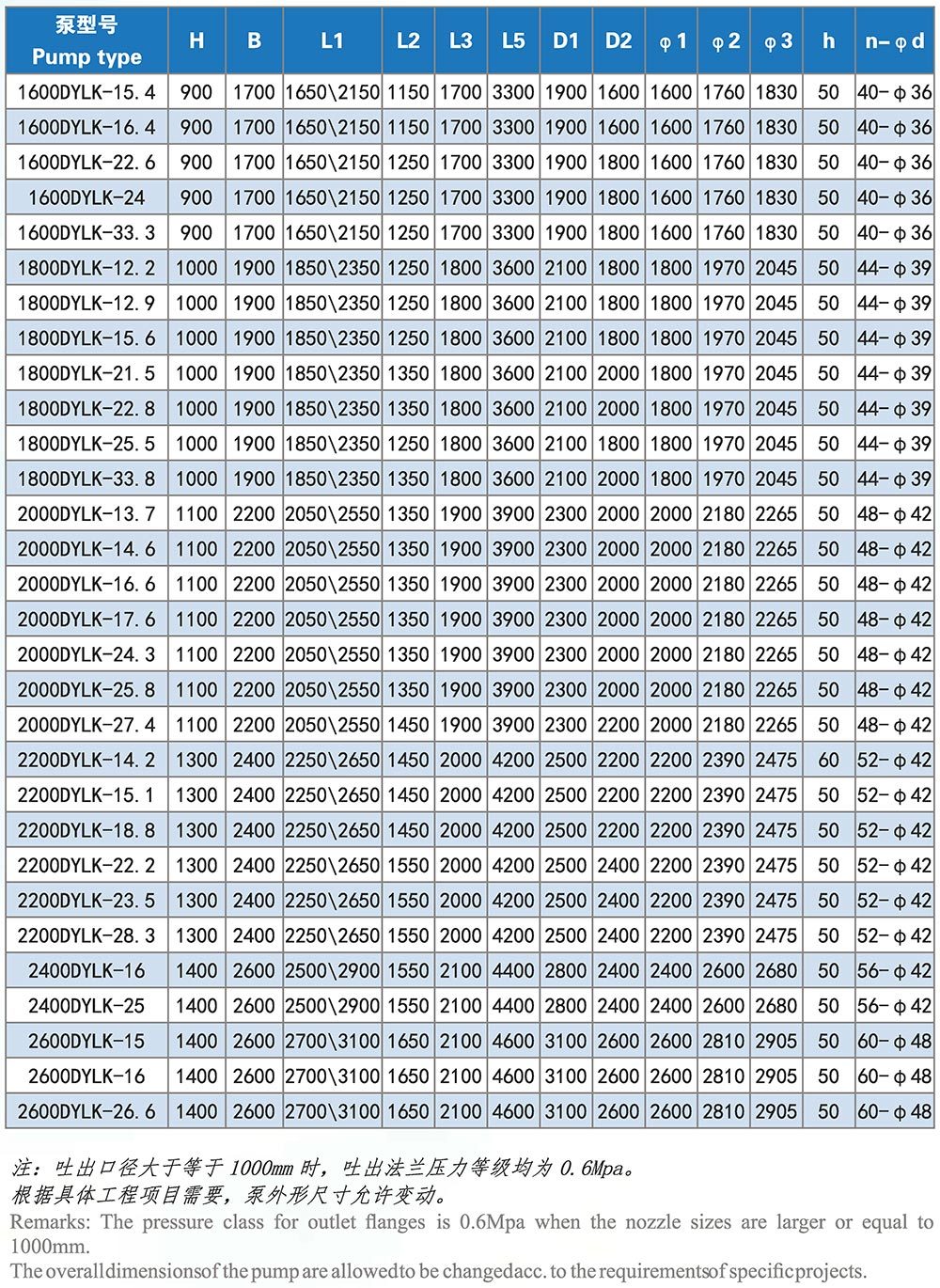

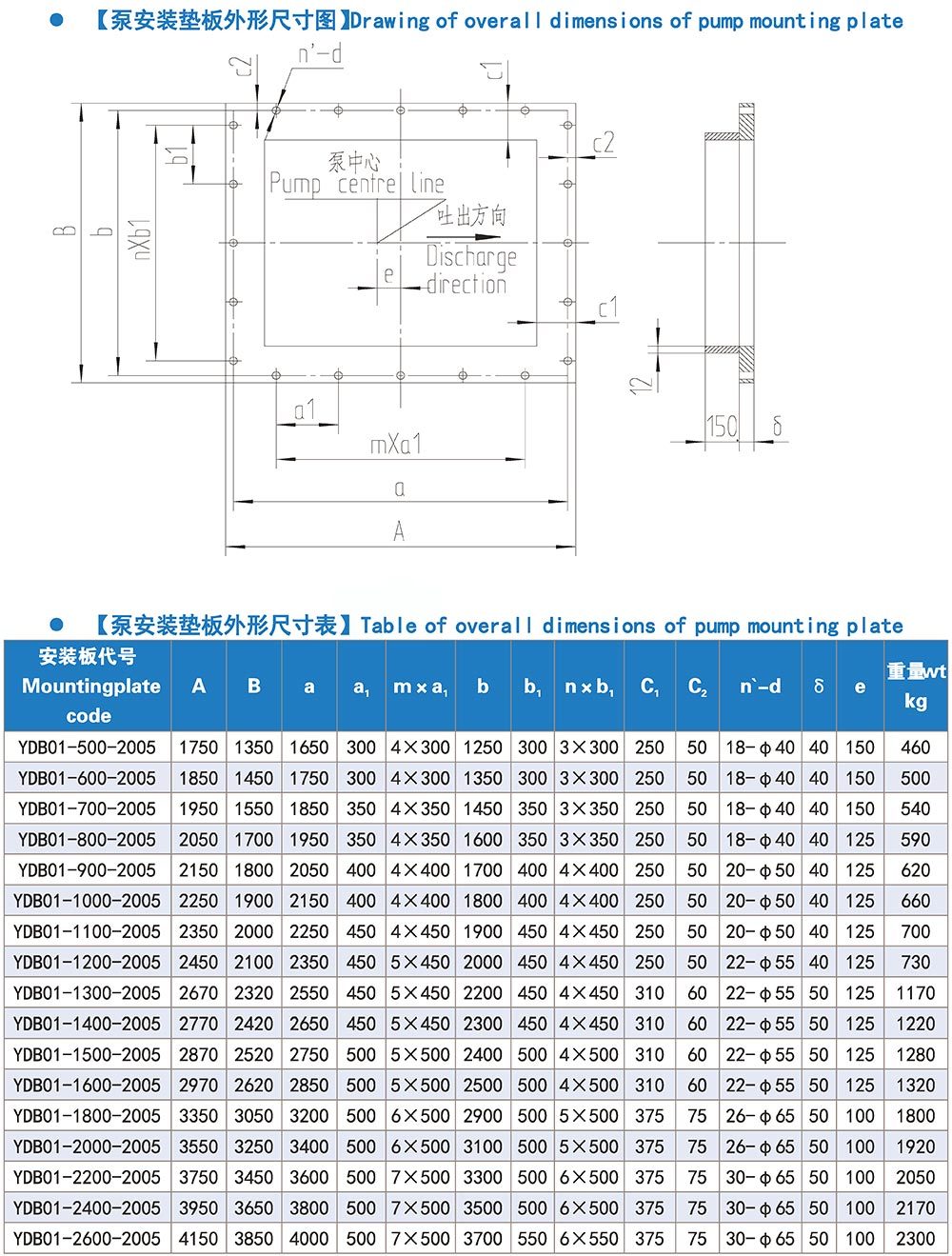

Appearance and installation dimensions

Key words:

Vertical long shaft pump

Why choose us

Why choose us

R & D Center

The processing workshop covers an area of about 5724 square meters, with ordinary lathes, vertical lathes, grinders, boring machines, gantry boring and milling machines and other large equipment. Turning can rotate each meter parts and add within 4.5 meters in diameter...

R & D personnel

The company's technical support. With technical support from professional energy-saving pump research institutes, laboratories, and strategic partners of pump manufacturing enterprises, it can design various types of products......

After-sales service

The whole process of quality management, including pre-sales and after-sales service for users, the quality of products is ultimately identified and evaluated by users in the process of use......

online message