DYMK floating platform water intake and sand pumping station

Classification:

Pump

Hotline:

Product Overview

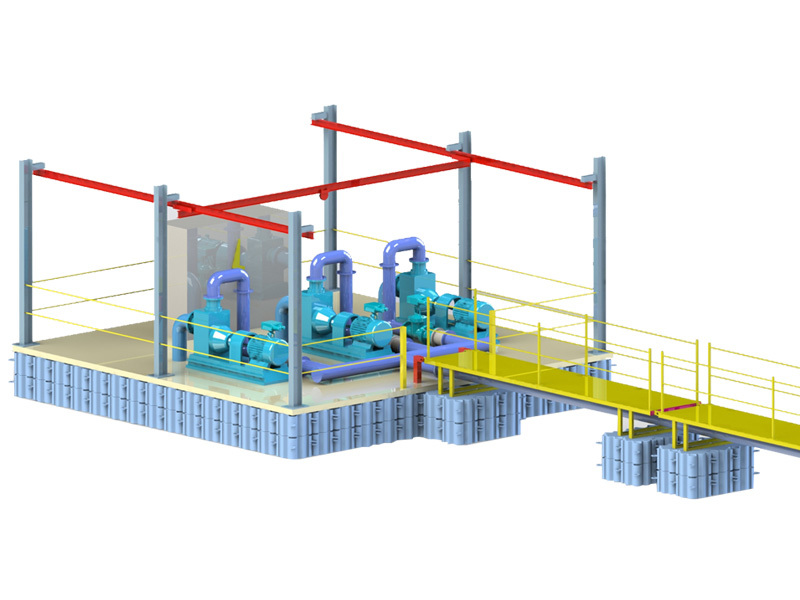

Using high molecular weight high-density HDPE modules as the carrier of the system platform, a steel equipment installation platform is built on it, forming a new type of water intake system for floating water and sand extraction that can efficiently transport media without being restricted by changes in water levels, riverbed movement, and geographical environments such as high mountains.

Structural Composition

The floating water and sand extraction pump station consists of floating barrels, platform frames, water intake pump groups, valves and outlet pipelines, lifting and maintenance devices, lighting systems, local control cabinets, PLC remote intelligent control systems, anchoring systems, and bridge drainage pipe systems, with a closed simple steel structure room on the platform.

Product Features

Easy and quick assembly, lightweight equipment, short construction period; equipment maintains water balance, is safe and stable; modular structure is convenient for transportation and simple to install. The product is highly practical, resistant to ultraviolet rays, cold and frost, oxidation, high temperatures, static electricity, acid and alkali corrosion, pollution-free, and does not harm the environment.

Application Range

Used for rivers, lakes, reservoirs, tailings ponds, drought-resistant water extraction, agricultural irrigation, and other domestic and industrial water diversion. The product has advanced technology, a wide range of adaptability, and significant economic benefits.

Advantage Comparison One

| Floating Water and Sand Extraction Platform | Steel Ship Water Intake Platform |

| 01 Greater Flexibility | 01 Previous water supply was limited by water levels |

| 02 No complex underwater structures | 02 High infrastructure investment |

| 03 Short construction period, quick results, low investment | 03 Poor water quality for extraction |

Comparison of Modular Floating Platforms and Steel Floating Boats

| Modular Floating Platform |

Steel Floating Boat |

|

| Carrier Material |

The floating barrel material uses strong HDPE (high molecular weight high-density polyethylene) with various chemical additives. |

Uses steel for anti-corrosion coating treatment; carbon steel is prone to chemical corrosion in humid environments and its service life is easily affected by the medium. |

| Safety |

The individual carrier specifications (500*500*400mm) are small; damage to a single unit does not pose a risk to the platform structure; |

Uses a segmented box structure (above 3000*2000*1000mm); damage to a single chamber may pose greater risks. |

| Installation |

Individual carriers are small in size and lightweight; they can be manually combined as needed with a short installation period and low cost. |

Assembly requires equipment assistance; installation costs are high. |

| Production Cycle |

Floating barrels are prefabricated in one piece with a fast production cycle; |

Floating bodies are welded into shape with very strict welding requirements; the production cycle is relatively long. |

| Transportation and Installation |

Regular shape facilitates loading and transportation. Lightweight (about 7kg), easy to install; on-site installation has relatively low site requirements. |

Box-type structure is larger in shape; transportation costs are higher; on-site installation requires lifting equipment and has higher environmental requirements. |

| Operating Costs |

No need for special government reviews every year; low cost. The carrier is maintenance-free for 15 years. |

Special operations require production licenses and classification society certification; production costs are high. Regular inspections and maintenance are required. |

Technical Features and Trends

* Water supply system from pump selection design

* Short construction period, low investment, quick results

* Electrical control system

* Floating barrels made from environmentally friendly high molecular materials in bulk production; stable quality, low cost, long service life

* Floating barrels have a lifespan four times longer than ordinary floating barrels

* Can be adjusted according to complex transportation conditions; installation does not require large cranes

* Greater flexibility with no complex underwater structures

Key words:

Floating platform water intake and sand pumping station

Previous Page

Next Page

Previous Page

Next Page

Why choose us

Why choose us

R & D Center

The processing workshop covers an area of about 5724 square meters, with ordinary lathes, vertical lathes, grinders, boring machines, gantry boring and milling machines and other large equipment. Turning can rotate each meter parts and add within 4.5 meters in diameter...

R & D personnel

The company's technical support. With technical support from professional energy-saving pump research institutes, laboratories, and strategic partners of pump manufacturing enterprises, it can design various types of products......

After-sales service

The whole process of quality management, including pre-sales and after-sales service for users, the quality of products is ultimately identified and evaluated by users in the process of use......

online message