DYCZ standardized industrial process pump

Classification:

Pump

Hotline:

Product Overview

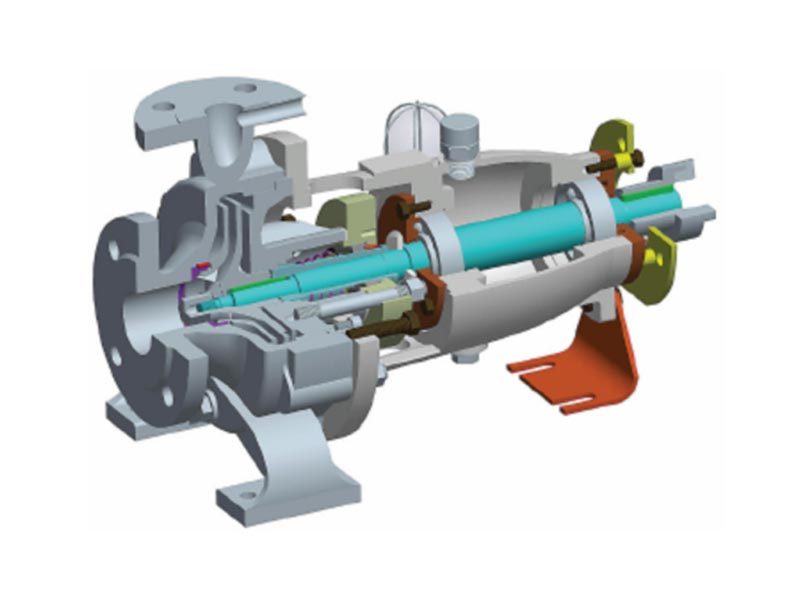

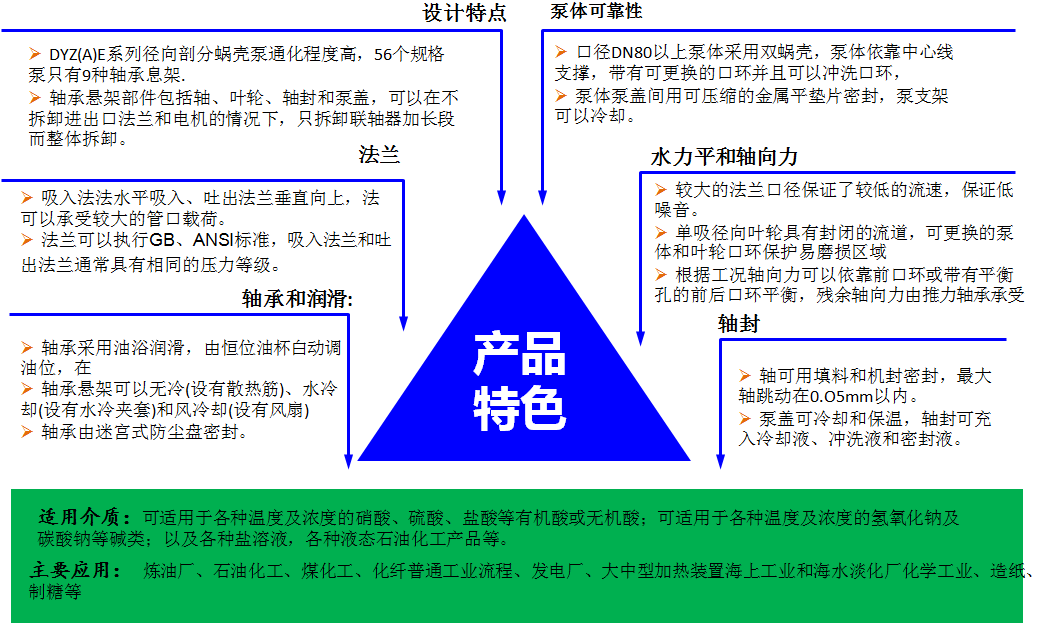

The DYCZ series standardized process pumps are developed and designed by our company based on advanced technologies of similar products from both domestic and international sources, in accordance with the ISO2858 international standard (National Standard GB3215). At the same time, relevant standards from API610 are referenced to improve the quality control level of the pump's main components. The shaft seal dimensions, structure, auxiliary piping system, operating clearance, and material control of the flow components of the DYCZ standardized process pump all meet the requirements of API610 standards, further enhancing the safety and reliability of chemical process pumps.

The DYCZ series standardized process pumps adopt CAD modular optimization structural design, featuring a novel and reliable pump structure with good interchangeability of components. The DYCZ full series includes 40 models and nearly 300 specifications, with only six types of power bracket components. The hydraulic model of the DYCZ series standardized process pumps is advanced, efficient, and has good cavitation performance, capable of meeting performance parameter requirements for various working conditions. The DYCZ series standardized process pumps have a high degree of standardization and strong universality, with installation dimensions conforming to ISO3661. They are currently widely used standardized process pumps in global industrial process systems and can be interchanged with other chemical process pumps such as IH, CZ, etc.

Main Uses

The DYCZ series standardized process pumps can be widely used in fields such as chemical engineering, metallurgy, power plants, food processing, sugar production, pharmaceuticals, papermaking, synthetic fibers, water supply, seawater desalination, environmental engineering, heating, and air conditioning. They are suitable for transporting low-temperature or high-temperature liquids, neutral or corrosive liquids, and clean liquids or liquids containing solid particles.

Performance Parameters

● Inlet Diameter: DN50~350mm

● Outlet Diameter: DN32~300mm

● Working Pressure: ≤2.5MPa

● Medium Temperature: -70℃~180℃

● Flow Rate: ~2000m³/h

● Head: ~160m

● Speed: 1450r/min and 2900r/min

● Matching Motor: ~315kW

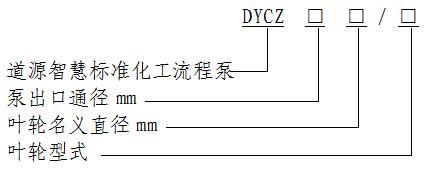

Model Description

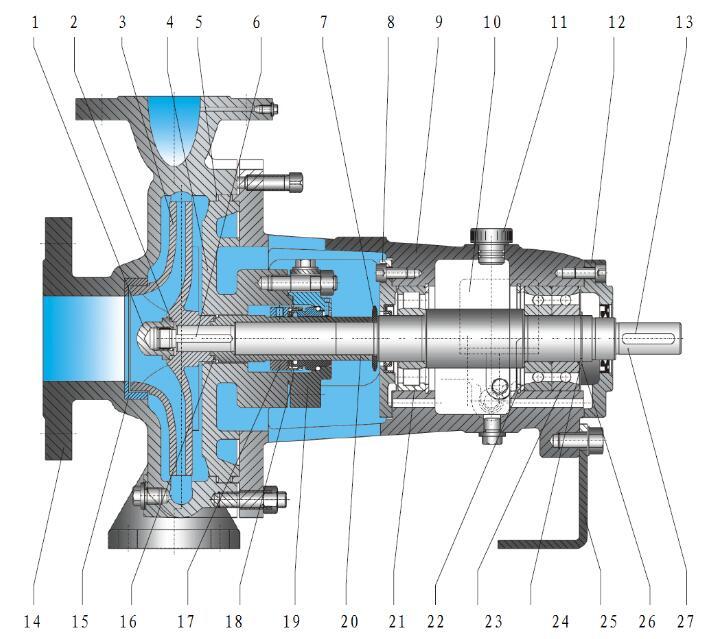

DYCZ Pump Structure Diagram

| Serial Number |

Name |

Serial Number |

Name |

Serial Number |

Name |

Serial Number |

Name |

| 1 |

*Impeller Nut |

8 |

Bearing Cover |

15 |

*Gland Ring |

22 |

Snap Ring |

| 2 |

*O-ring |

9 |

Bearing Frame |

16 |

*Seal Ring |

23 |

*Rolling Bearing |

| 3 |

Impeller |

10 |

Constant Level Oil Cup |

17 |

*Mechanical Seal |

24 |

Retaining Ring |

| 4 |

Pump Cover |

11 |

Vent Oil Plug |

18 |

*Seal Gasket |

25 |

Support Foot |

| 5 |

*Seal Gasket |

12 |

Bearing Cover |

19 |

Seal Cover |

26 |

Snap Ring |

| 6 |

Key |

13 |

Key |

20 |

*Shaft Sleeve |

27 |

Shaft |

| 7 |

Retaining Ring |

14 |

Pump Body |

21 |

*Rolling Bearing |

|

|

Note: Items marked with * are consumable parts.

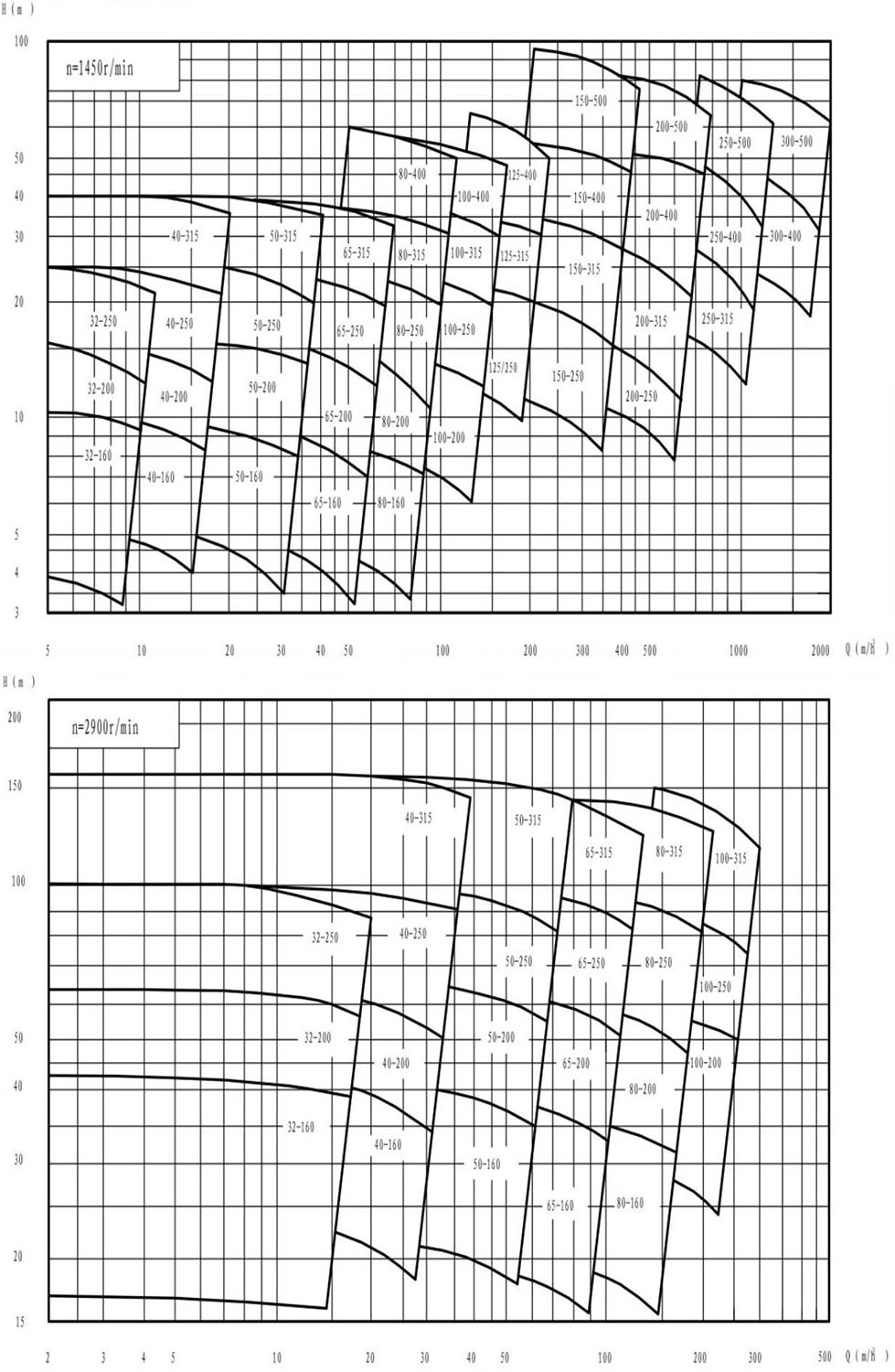

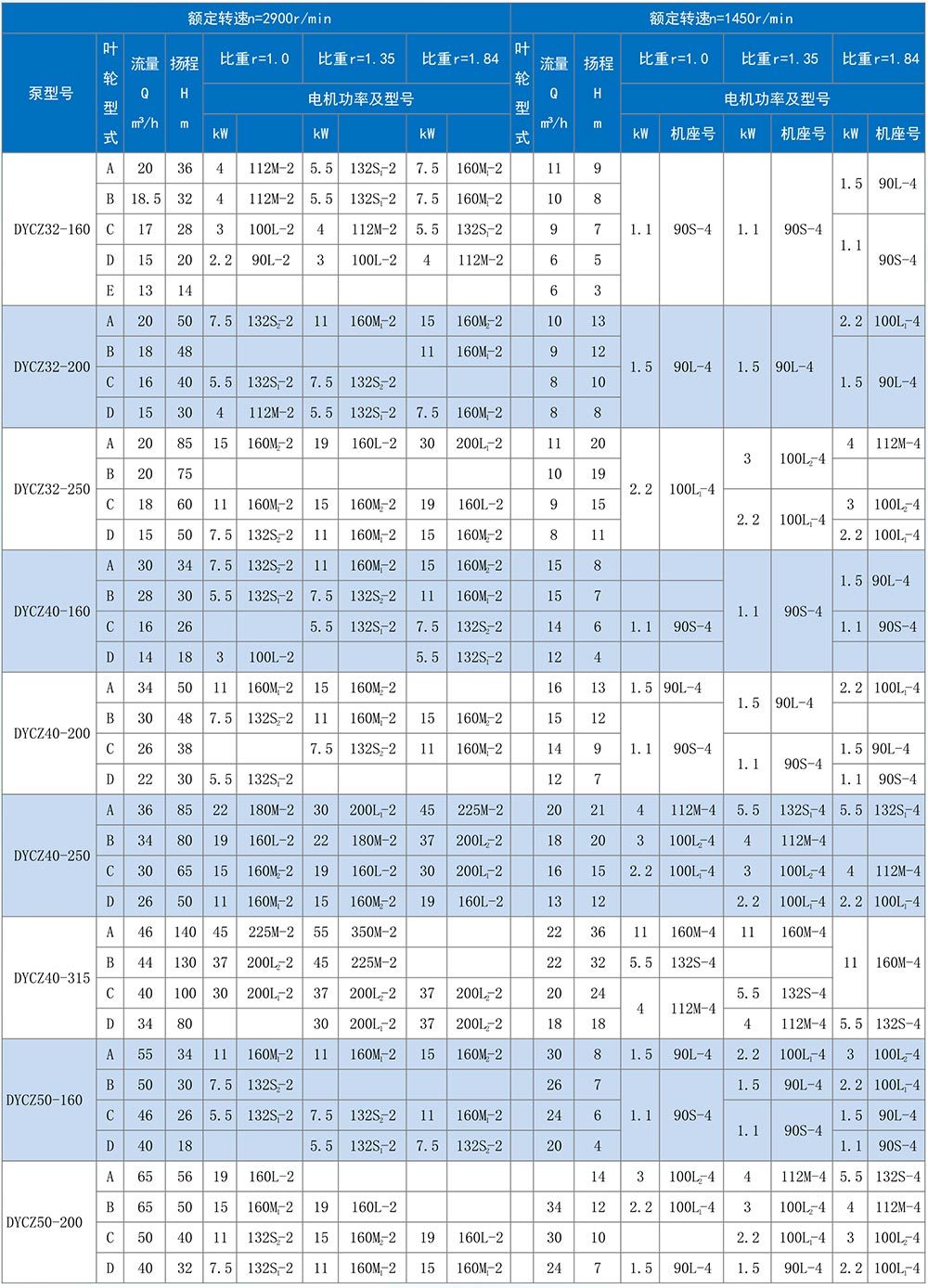

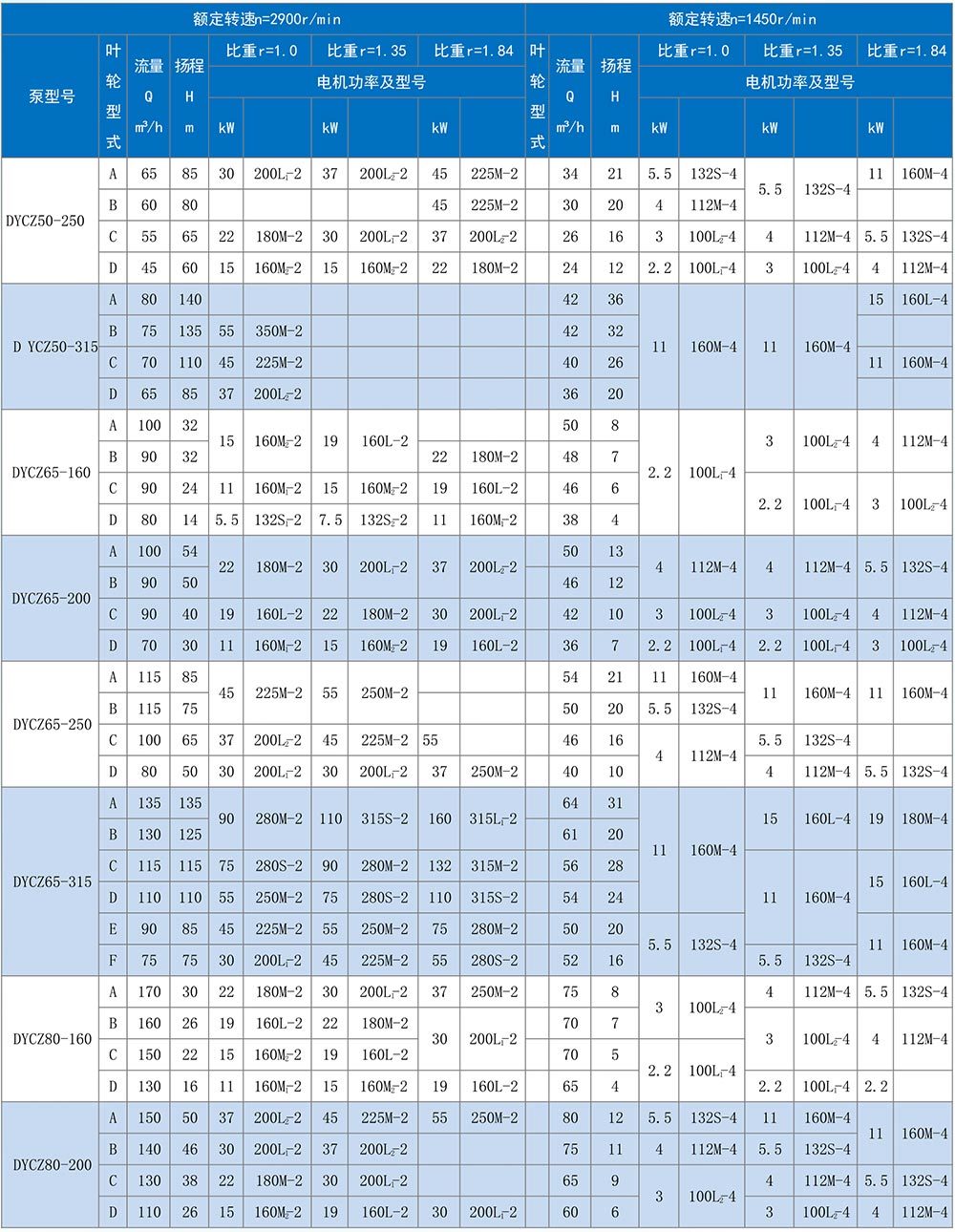

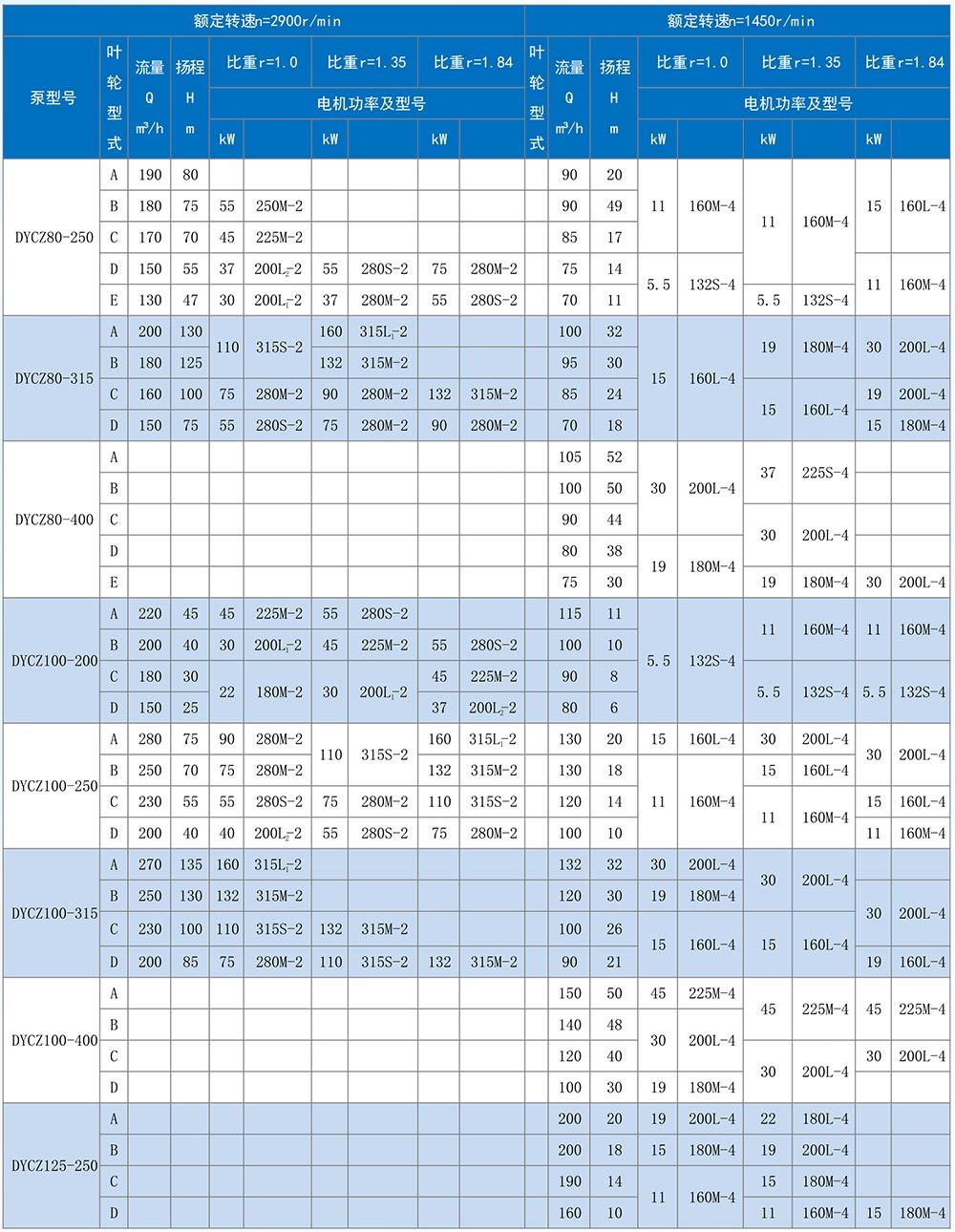

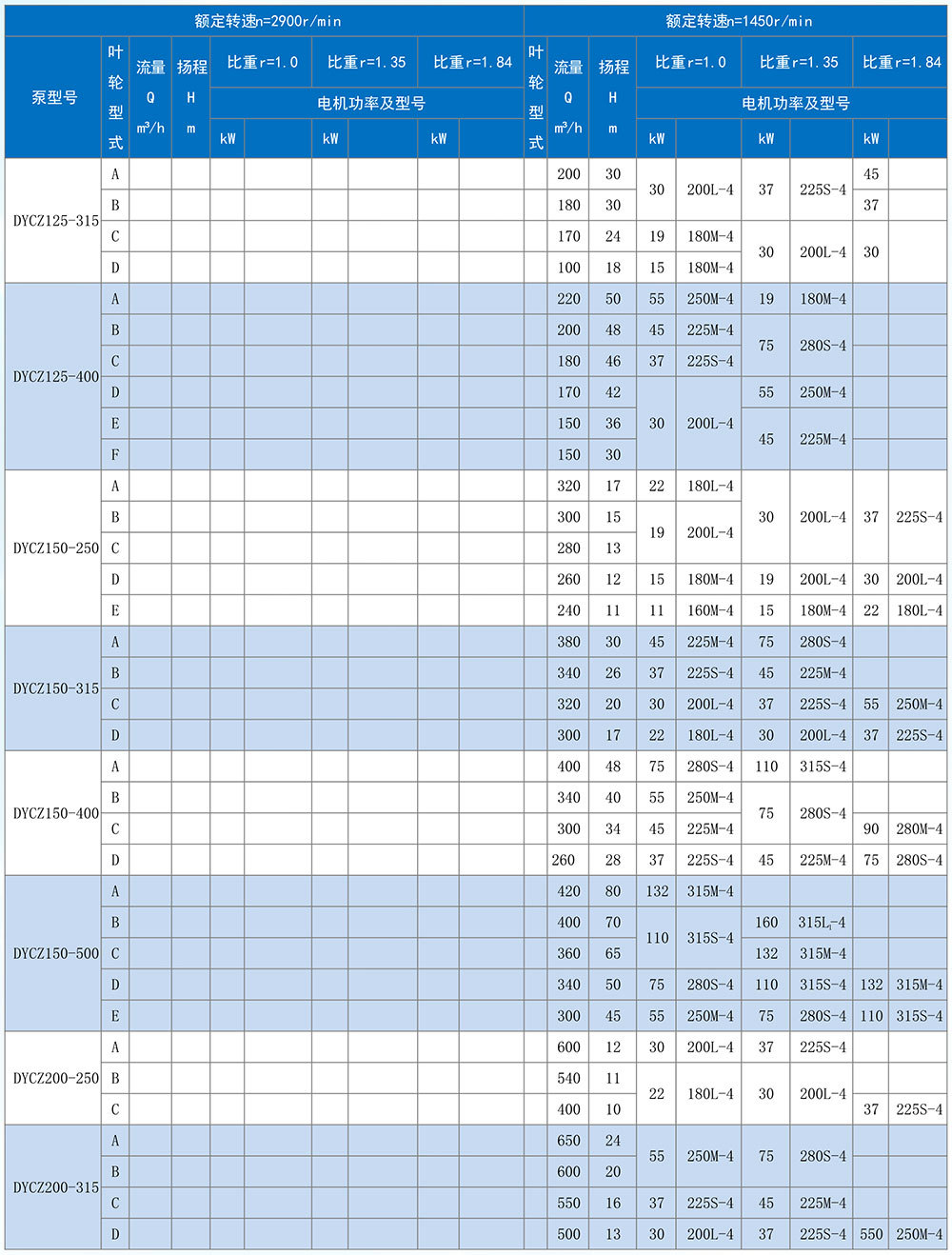

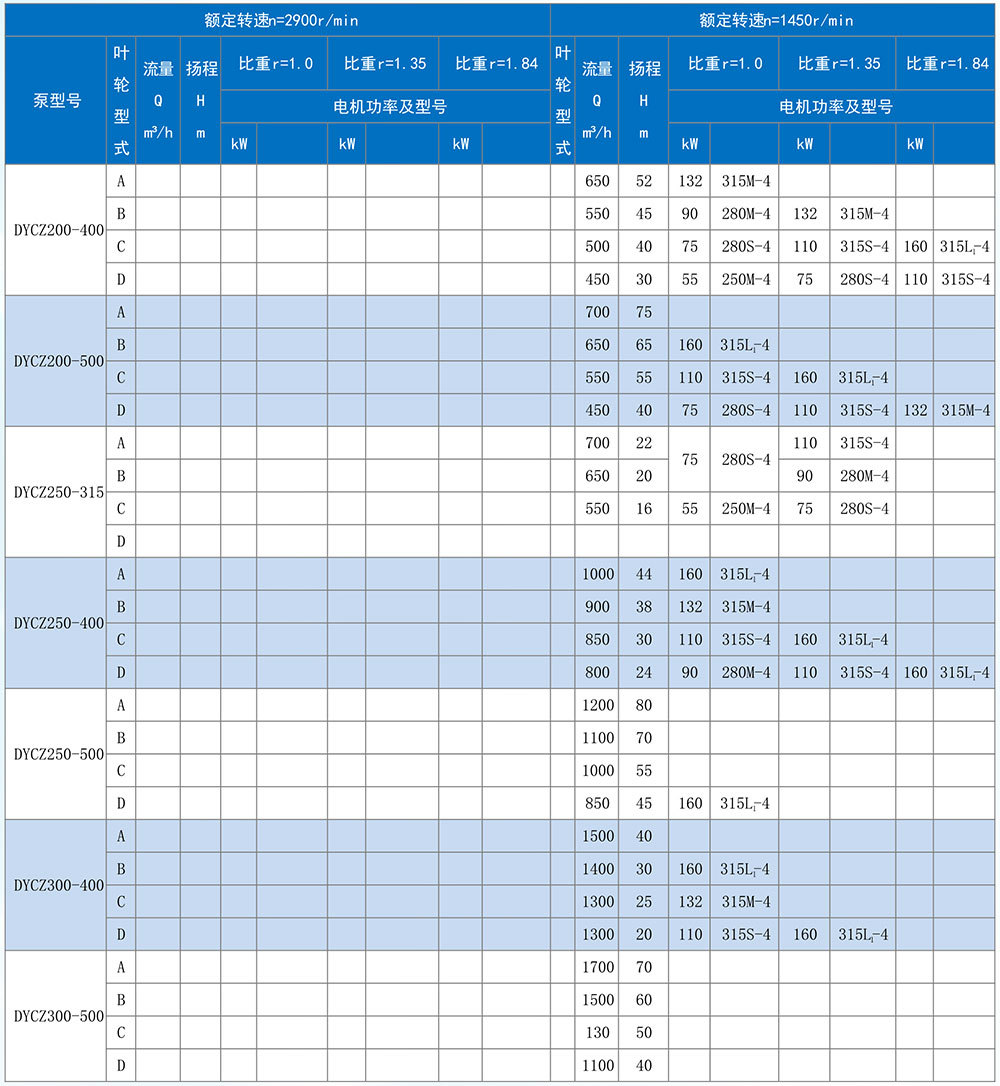

DYCZ Pump Type Spectrum Diagram

Note:

*The order contract for the pump type should also specify the impeller type, matching motor power, and speed.

*For performance tables without matching motor power, calculations should be made based on the pump's flow rate, head, medium density, and pump efficiency.

*The parameters in the performance table refer to the performance parameters when the pump is conveying clean water or similar to clean water. When the viscosity of the conveyed medium is larger, performance conversion must be performed; as the viscosity increases, the pump flow rate and head decrease while shaft power increases.

Key words:

Standardized industrial process pump

Previous Page

Next Page

Previous Page

Next Page

Why choose us

Why choose us

R & D Center

The processing workshop covers an area of about 5724 square meters, with ordinary lathes, vertical lathes, grinders, boring machines, gantry boring and milling machines and other large equipment. Turning can rotate each meter parts and add within 4.5 meters in diameter...

R & D personnel

The company's technical support. With technical support from professional energy-saving pump research institutes, laboratories, and strategic partners of pump manufacturing enterprises, it can design various types of products......

After-sales service

The whole process of quality management, including pre-sales and after-sales service for users, the quality of products is ultimately identified and evaluated by users in the process of use......

online message