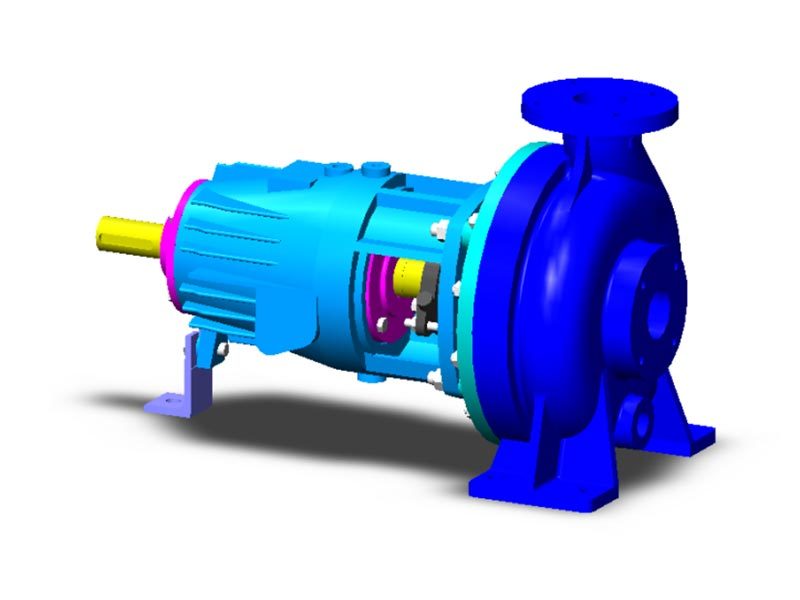

DYP type vortex non-clogging pump

Classification:

Pump

Hotline:

Product Overview

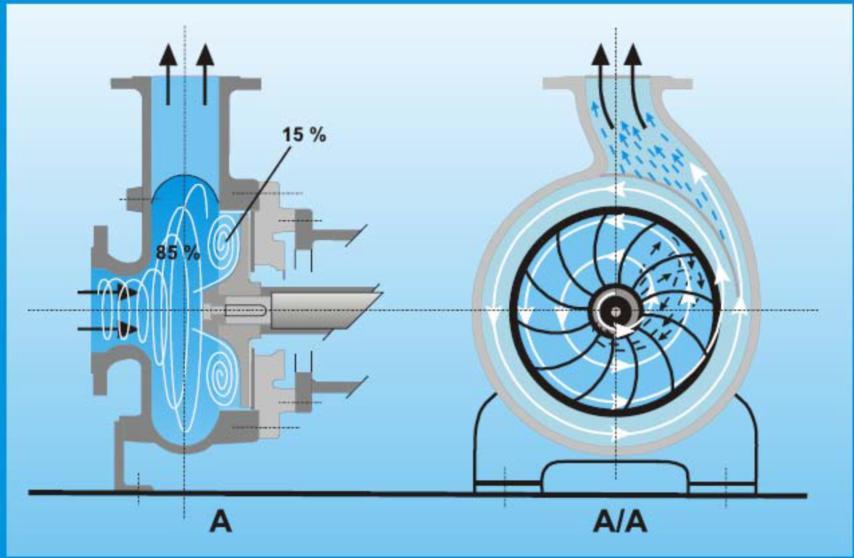

The DYP type pump is the latest product developed by our company based on the introduction of advanced technology from Japan's Ebara Corporation. The impeller is retracted into the pump chamber behind the pressure water chamber, and when the impeller rotates, it forms a through flow and a circulation flow in the bladeless chamber in front of the impeller.

The through flow enters the pump chamber through the flow passage between the impeller blades and flows out, while the circulation flow circulates in the bladeless chamber. Since the middle of the circulation flow is a low-pressure area, solid particles fall into this area and flow out under the influence of eddies. Therefore, most solid materials can flow out directly from the bladeless chamber without passing through the impeller. This pump adopts a completely eddy current shape, and the gap between the impeller and pump casing is the same as the discharge outlet diameter. Therefore, this type of pump has excellent non-blocking performance for sewage, sludge, fibers, etc. The pump is efficient, has low vibration, and operates smoothly. The inlet of the impeller has a stirring effect on foreign objects, thus providing good cavitation performance. It can transport sewage, sludge, waste, and high-concentration slurries, with the maximum particle size in the liquid not exceeding the discharge outlet diameter. The medium temperature ranges from 0℃ to 80℃, with an allowable inlet pressure of 0.29MPa (3kgf/cm2) and a maximum operating pressure of 0.629MPa (7kgf/cm2). The performance parameters listed in this catalog are obtained under experimental conditions with normal temperature clear water (specific gravity of 1).

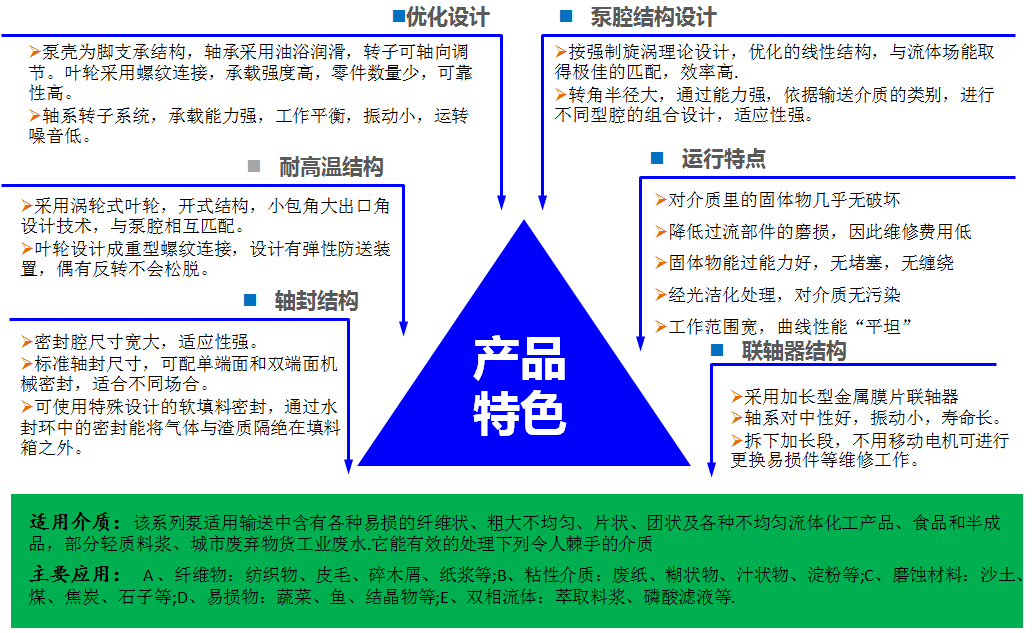

Non-Blocking Eddy Current Pump Features

Non-Blocking:The concave impeller ensures that the medium passes through the pump casing without obstruction during operation. Therefore, it allows solid particles in the medium that do not exceed the pump inlet size to pass smoothly without causing blockage at the pipe entrance.Improved Hydraulic Efficiency:

The unique design of the eddy current pump forms an axial flow passage inside the pump casing to ensure that solid particles in the medium can pass quickly and smoothly through the pump casing while reducing internal recirculation, thereby minimizing negative impacts on hydraulic efficiency and pump lifespan.Low Medium Wear:

Since liquid flows freely through the pump casing, fluid and impeller are isolated, with only 15% of the medium directly contacting the impeller. Fragile solids such as crystals and carbon compounds pass through the pump chamber with minimal damage. It is particularly suitable for applications requiring low shear stress on mediums.Simple Design:

Due to the hydraulic center of blades inside the pump casing and its simple open design, radial loading on the main shaft and bearings is minimal. Even in cases of extreme wear on the impeller, its coaxial nature does not affect mechanical balance.Low Operating Costs:

With improved hydraulic efficiency of eddy current pumps compared to general eddy current pumps, they consume less power. This gentle pumping method also significantly extends the lifespan of pumps and spare parts, greatly reducing operating costs.Reliability:

This robust and simple design, along with proper material selection, ensures a long service life. Time has proven that eddy current pumps require fewer spare parts than other brands of centrifugal pumps.Standardized Specifications:

To achieve interchangeability of product components between pumps of different sizes and designs, eddy current pumps use standard specifications for spare parts, minimizing spare part quantities.Parameter Range:

Flow Rate: 36∽480m3/h

Head: 10∽60m

Working Temperature: 0℃∽80℃

Rotation Direction: Viewed from drive end direction, pump rotates clockwise

Allowable Inlet Pressure: 0.29MPa

Model Description:

Example: DYP80×50-A

DY: Changsha Daoyuan Intelligent Fluid Technology Co., Ltd.

P: Non-Blocking Eddy Current Pump

80: Pump inlet diameter is 80mm

50: Pump outlet diameter is 50mm

A: First cut of impeller

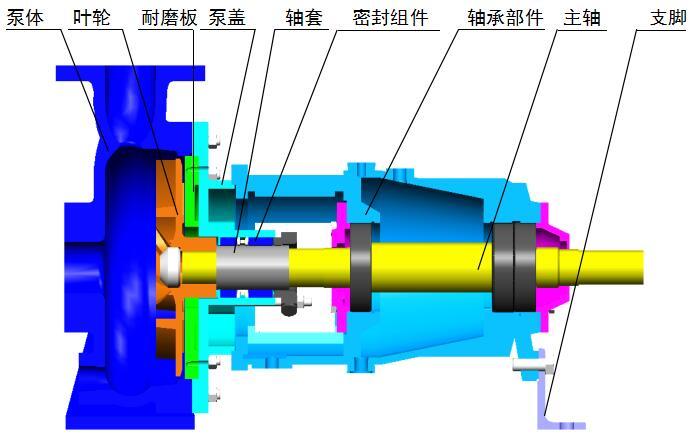

Structural Type

The pump is horizontally installed with axial suction and vertical discharge. The base supports the pump body; the rotor can be extracted from behind without disassembling pipes or pumps during maintenance. The shaft seal type uses packing seal.

Main Parts Material:

Optional materials include carbon steel, high alloy steel (Cr26 alloy, Cr27Ni5, A49 (Cr30+Ni, Cu, Mo)),304,316,316L,CD4Mcu,2205,2507,904L etc., or other materials as required by users.

Complete Set Range:

Complete supply includes pump, motor and base.

Main Applications

Metallurgical Ore Dressing: Acid washing process ore dressing

Automotive Industry: Paints for coating, emulsions, grinding cutting fluids and corundum slurries; emulsifiable oils and fine iron filings; paint sludge; solvent-based/water-based primers; mixed sludge; phosphate sludge.

Sugar Industry: Beets; beet roots; leaves and water plants; lime milk at95 ℃; lime (milk) residue from sedimentation tanks; diatomaceous earth; unfiltered sugar juice.

Construction Industry: Aerated concrete slurry; sand; gravel; stone materials; marble dust solutions; phenolic oil solutions.

Textile Industry: Natural and synthetic fibers; coarse dyeing agents; fiber wastewater; wool washing.

Excavation Industry: Sand; gravel; landslides; lake and port cleaning.

◆挖掘工业:沙子,沙砾,山体滑坡,湖和港口清洁。

◆ Fiber Industry: Fiber cement slurry, asbestos, leather fiber, glass fiber, textile fiber, nitrocellulose.

◆ Power Station: Dust, dust-proof net slurry.

◆ Chemical Industry: Crystal suspensions, fiber slurry, latex, polystyrene solution, 50% soda solution, hot brine, laundry powder slurry, zinc ore slurry, suspension coatings, bicarbonate slurry, catalytic sludge, etc.

◆ Steel Industry: Scale, gray slurry, mixture of coke and coal water, suspended borax.

◆ Shipbuilding Industry: Sewage pumps, bilge pumps, fish waste.

◆ Petrochemical Industry: Sewage, catalytic slurry, oil containing carboxylic acid, drilling mud, raw coke tar.

◆ Paper Industry: Unprocessed waste paper, straw pulp, rag pulp, hot grinding pulp, 80% kaolin content, bagasse, tailings, pulper residue.

◆ Wastewater Treatment: Unfiltered sewage, untreated sludge, treated sludge, grid channel pumps, slaughterhouse wastewater, all municipal and industrial wastewater, granular activated carbon.

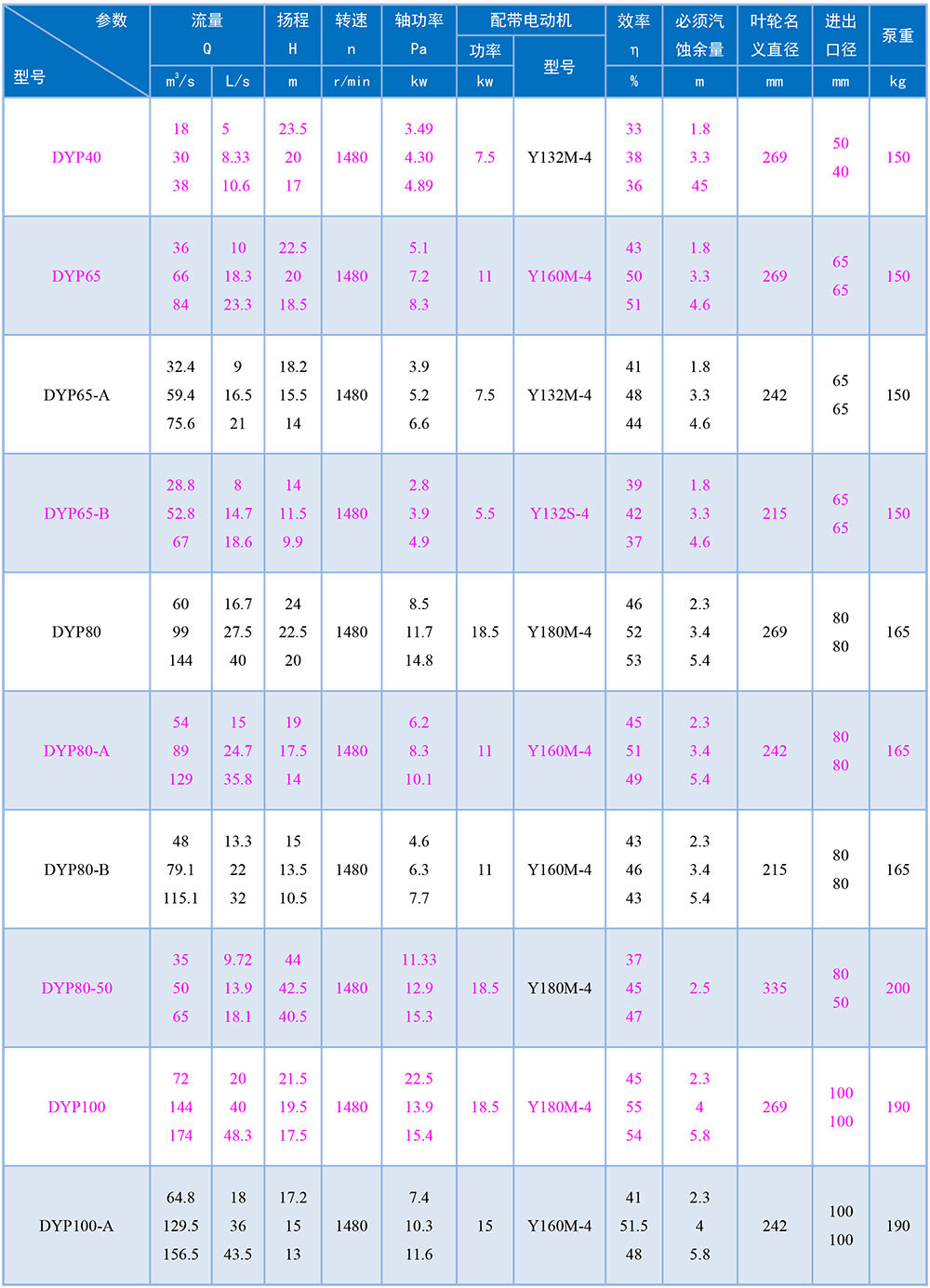

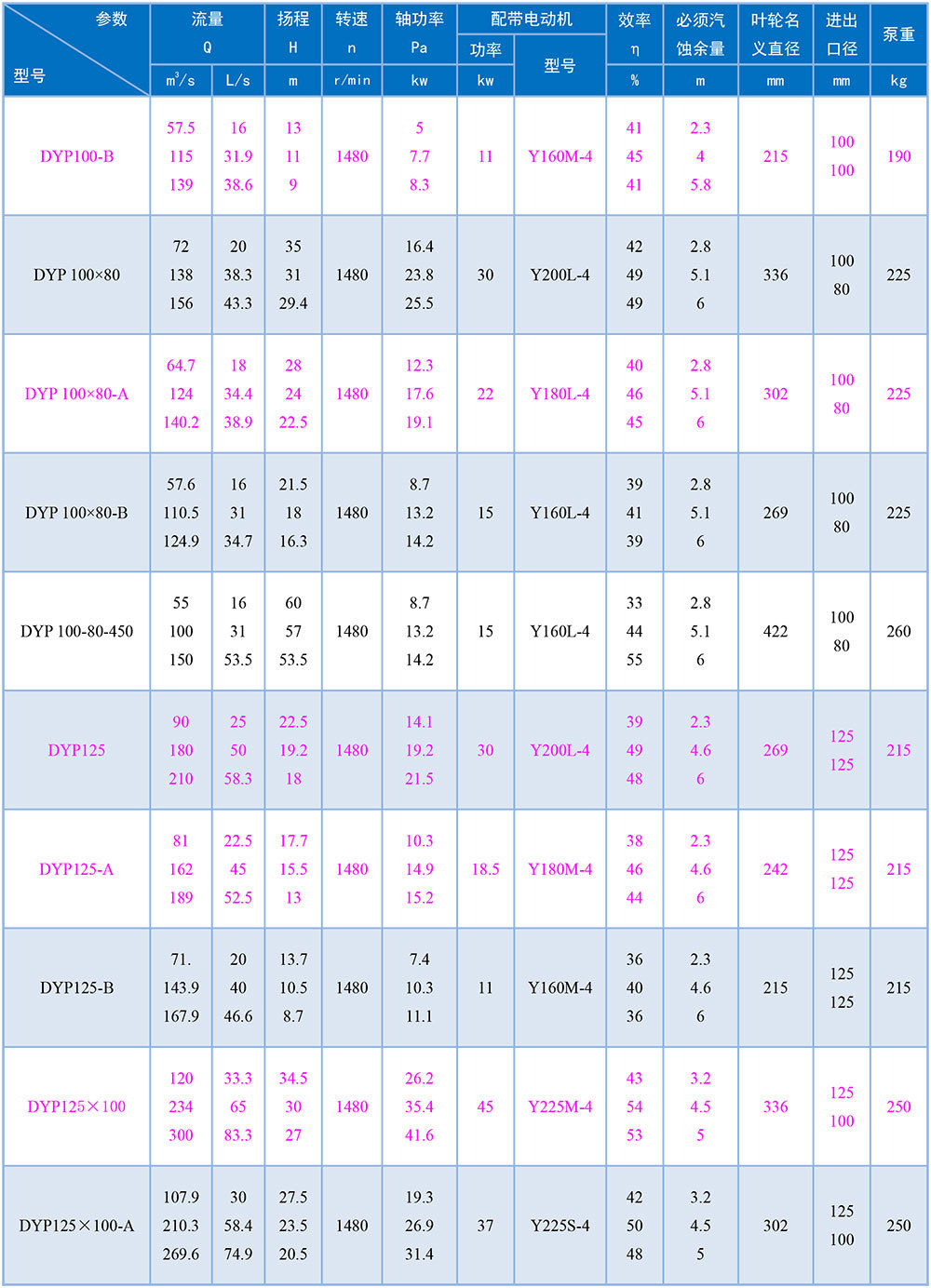

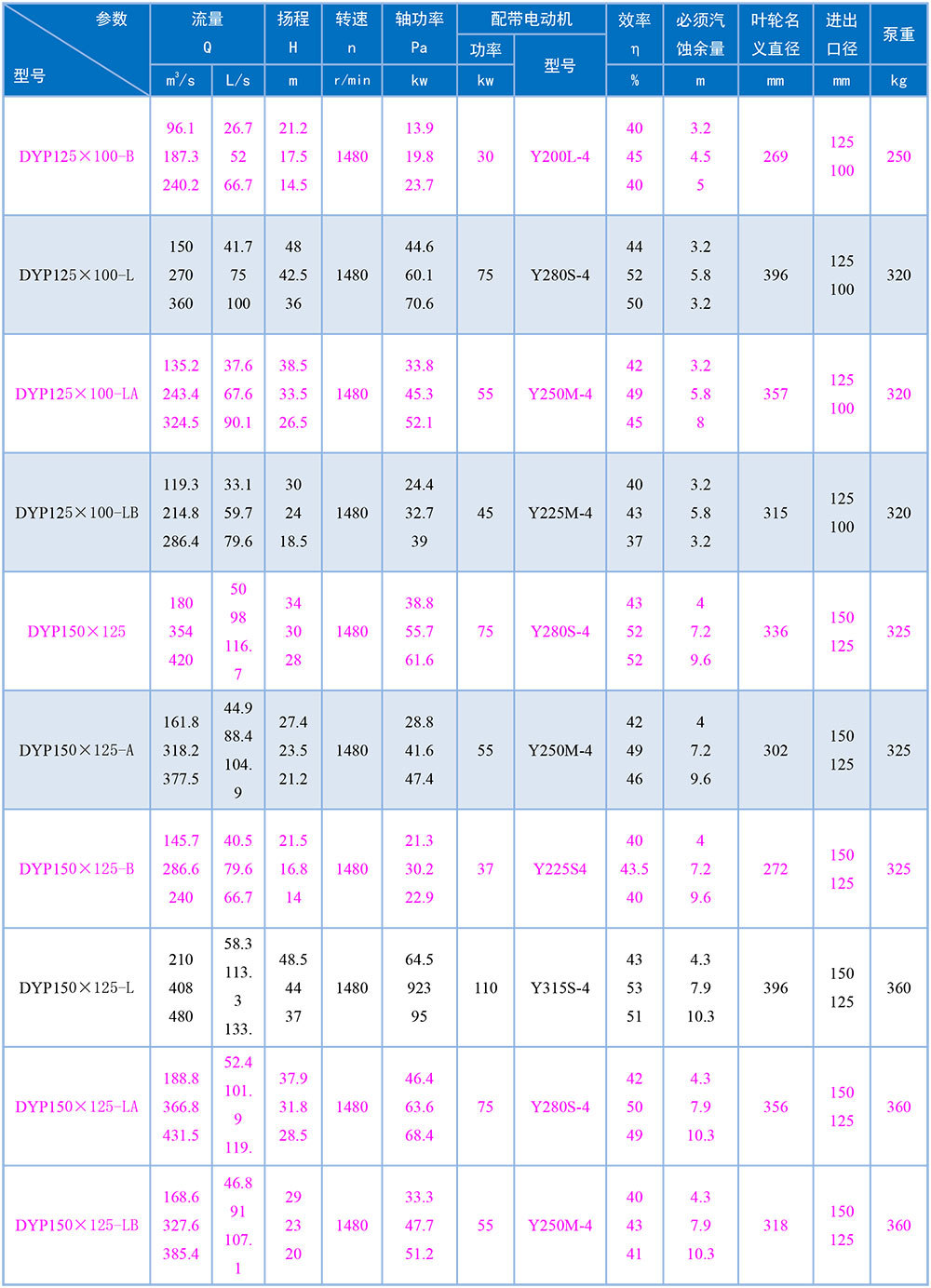

DYP type vortex non-clogging pump performance parameter table.

Key words:

Vortex non-clogging pump

Previous Page

Previous Page

Why choose us

Why choose us

R & D Center

The processing workshop covers an area of about 5724 square meters, with ordinary lathes, vertical lathes, grinders, boring machines, gantry boring and milling machines and other large equipment. Turning can rotate each meter parts and add within 4.5 meters in diameter...

R & D personnel

The company's technical support. With technical support from professional energy-saving pump research institutes, laboratories, and strategic partners of pump manufacturing enterprises, it can design various types of products......

After-sales service

The whole process of quality management, including pre-sales and after-sales service for users, the quality of products is ultimately identified and evaluated by users in the process of use......

online message