DYZJ series slurry pump

Classification:

Pump

Hotline:

Product Overview

The DYZJ series slurry pump is a new generation of high-efficiency heavy-duty centrifugal slurry pump developed by our company based on years of mature experience in the research and application of advanced domestic slurry pumps, and on the introduction of advanced foreign technology, incorporating the technical advantages of similar foreign products. It is mainly used for the circulation transportation of volcanic FGD limestone, lime, and gypsum slurry, and is also used in industrial sectors such as metallurgy, mining, coal, building materials, and chemicals for transporting slurry containing corrosive solid particles. This series of products features a reasonable structure, reliable operation, and long service life.

Applicable Slurry Medium Characteristics

pH value: 2.5∽13Chloride ion (Cr-) concentration: ≤60000ppm

Weight concentration: ≤60%

Medium temperature: ≤120℃

Maximum solid particle size: ≤50mm

Parameter Range

Flow rate Q: 150~8300m3/h

Head H: 10~58m

Model Description

10- Pump outlet diameter multiplied by 25 (i.e., the pump outlet diameter is 250mm)

DYZJ- Xiangdaoyuan Heavy-duty Slurry Pump

(K) - indicates a coated lining; if not indicated, the flow parts are all metal.

25- The design speed ratio of the pump divided by 10.

J - indicates a change in the rated speed of the pump.

A - indicates the first change in impeller outer diameter; A, B, C... and so on.

Structural Type

All-metal flow parts

Coated lining or rubber lining

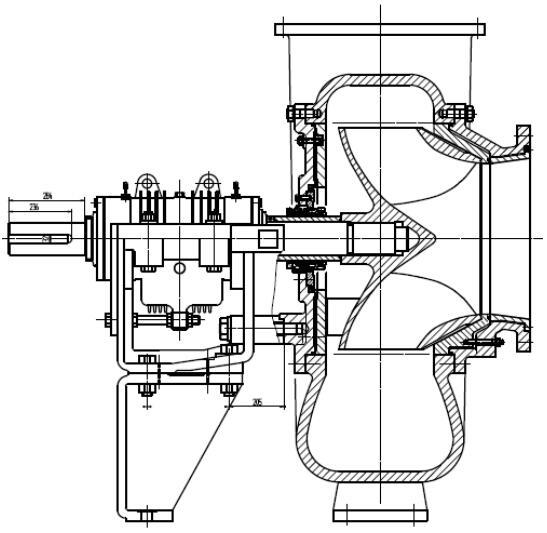

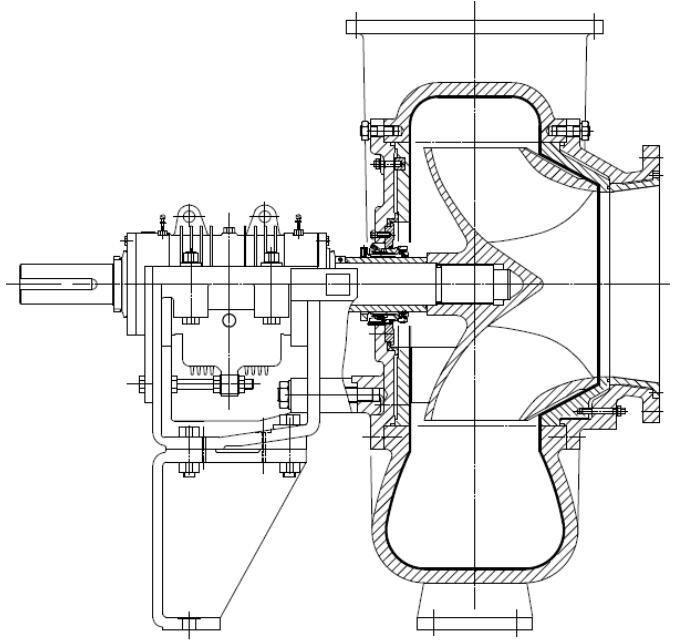

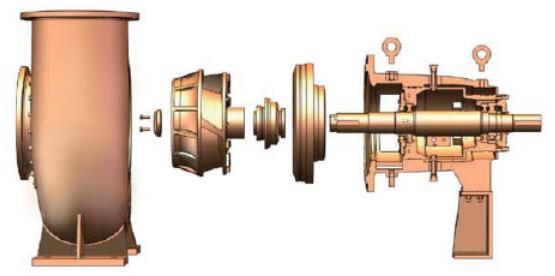

The pump is a horizontal, single-stage, single-suction cantilever centrifugal slurry pump; this type of pump operates at high speed and uses a wide channel centrifugal impeller, with auxiliary blade structures cast on the back of the impeller; the pump cover adopts a rear pull-out structure. The pump body has replaceable wear-resistant metal lining or rubber lining, and the impeller is made of wear-resistant metal. The pump body can adopt different outlet angle directions according to user requirements.

Rear pull-out structure

The pump is connected to the motor or speed control mechanism through an extended diaphragm flexible coupling. During maintenance, it is not necessary to disassemble the inlet and outlet pipelines to withdraw the rotor components for maintenance.

The bearing body component adopts a bracket structure; the pump end uses imported double-row tapered roller bearings, while the drive end uses two disc cylindrical roller bearings. It is lubricated with thin oil.

The shaft seal adopts a cartridge mechanical seal.

Rotation Direction

When viewed from the drive end, the pump rotates clockwise. The rotation direction can also be changed according to user site pipeline installation needs.

Technical Features

Adopts excellent foreign hydraulic models and advanced computer simulation analysis technology (Solidworks, ANSY, Flowworks, etc.), ensuring reliable performance and high efficiency.

The material selection for the pump's flow parts is reasonable and advanced with a long service life. It is coated with KD.L-201 wear-resistant lining to meet the wear-resistant and corrosion-resistant requirements for transporting different media slurries.

Incorporates structural advantages from large domestic and foreign slurry pumps and mud boats; it features an advanced structure that is simple to maintain and operates reliably.

The bearing body adopts a simplified structure that adjusts the position of the impeller in the pump chamber by adjusting bearing components to keep the pump group in a high-efficiency operating state.

The shaft seal adopts a cartridge mechanical seal that is easy to install and maintain without requiring external clean industrial flushing water.

Main Parts Material

Serial Number

Part Name

| All-metal Pump |

(K) Pump coated with KD.L-201 |

Suction Liner |

(A49 or Cr30A or Cr26) |

| 1 |

(QT500-7 + Coated Lining) |

(Pump Body (Shell)) |

(Pump Cover (Guard)) |

| 2 |

(Impeller) |

(Pump Body (Shell)) |

(Pump Cover (Guard)) |

| 3 |

(A49 or CD-4MCu (GX2Cr25Ni6Mo3Cu3N)) |

(Pump Body (Shell)) |

(Pump Cover (Guard)) |

| 4 |

(Shaft) |

(0Cr17Ni12Mo2 (316)) |

|

| 5 |

(Shaft Sleeve) |

(0Cr18Ni12Mo2Ti or 4MCu (GX2Cr25Ni6Mo3Cu3N)) |

|

| 6 |

(Bearing Body) |

(Bearing Bracket) |

|

| 7 |

(Note: KD.L-201 is a new type of anti-corrosion and wear-resistant spray material developed by the Key Laboratory of CFC at the School of Aerospace and Materials Engineering, National University of Defense Technology.) |

HT250 |

|

| 8 |

(Complete Set Range) |

HT250 |

|

(Complete supply includes pump, motor, speed control mechanism, coupling, common (or pump itself) base plate.)

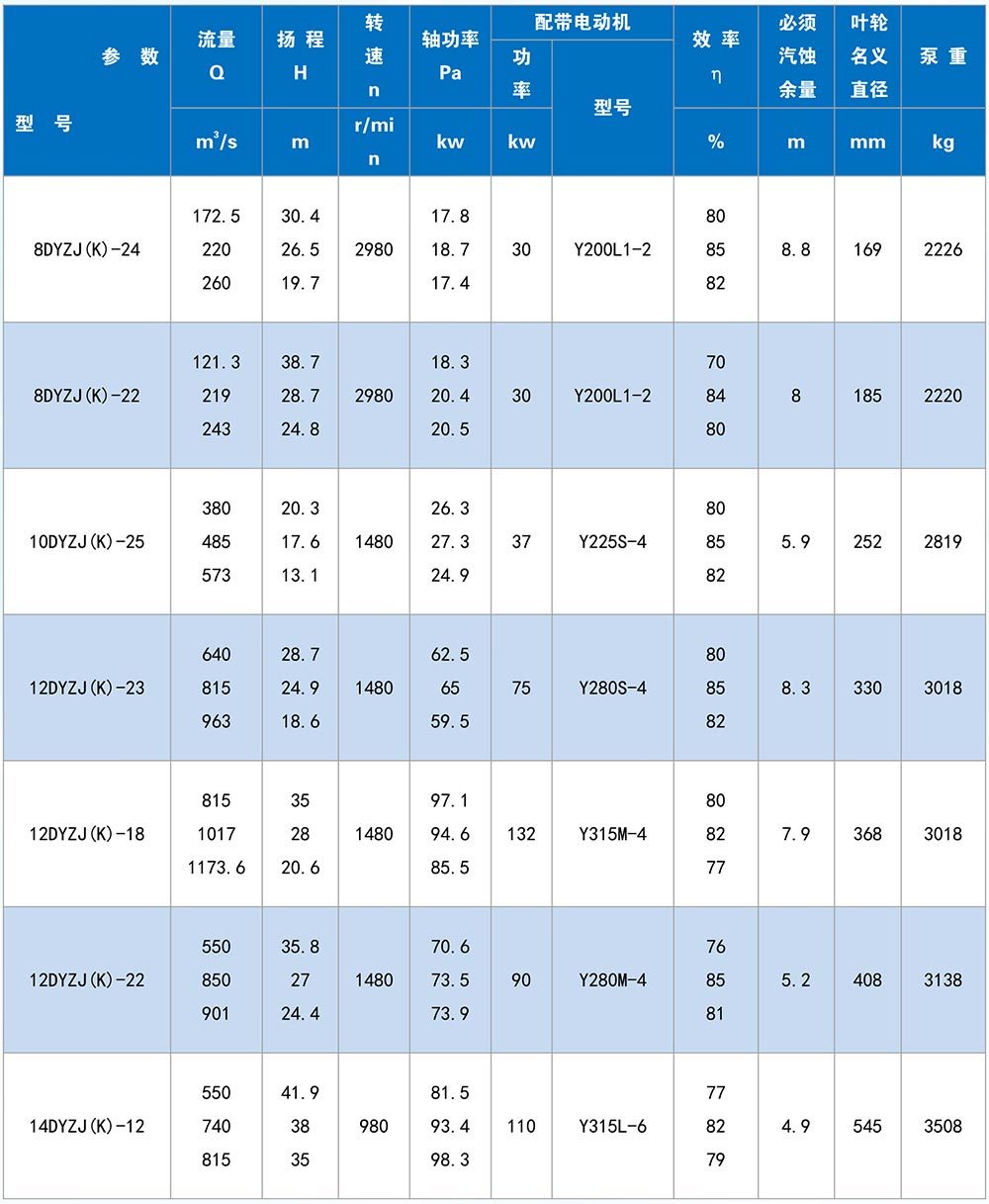

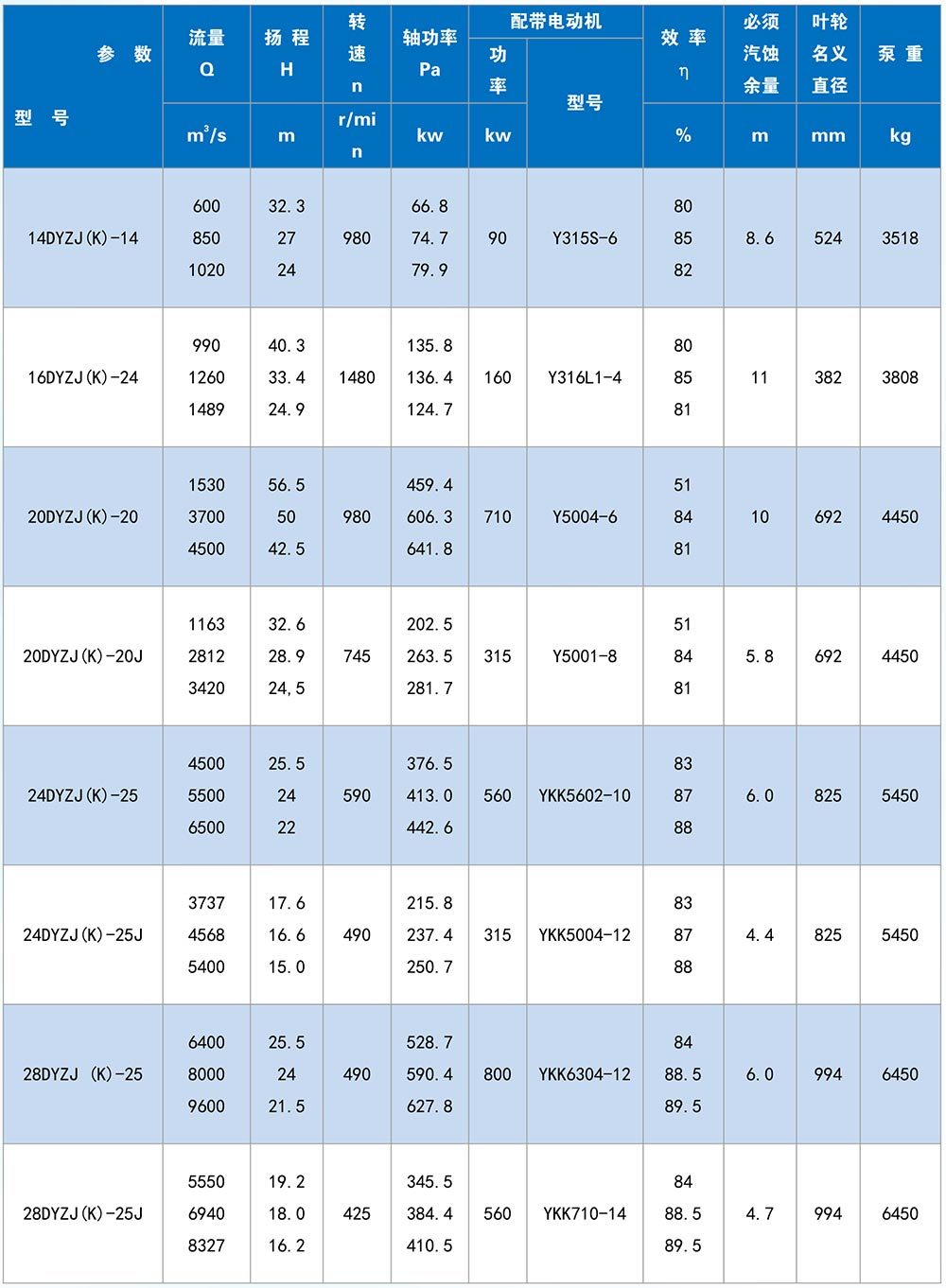

(Pump Clear Water Performance Table)

(Note: The above motors are selected based on a slurry specific gravity of 1.15. When selecting motors, users should calculate motor matching power based on specific medium specific gravity.)

泵清水性能表

注:1、以上电机均按浆体比重1.15计算选择,用户选择电机时,应根据具体介质比重核算电机配套功率;

2. It can also be equipped with a high-speed motor + speed regulation mechanism or a small range of impeller diameter changes to meet different parameter requirements of users.

Key words:

Slurry pump

Previous Page

Next Page

Previous Page

Next Page

Why choose us

Why choose us

R & D Center

The processing workshop covers an area of about 5724 square meters, with ordinary lathes, vertical lathes, grinders, boring machines, gantry boring and milling machines and other large equipment. Turning can rotate each meter parts and add within 4.5 meters in diameter...

R & D personnel

The company's technical support. With technical support from professional energy-saving pump research institutes, laboratories, and strategic partners of pump manufacturing enterprises, it can design various types of products......

After-sales service

The whole process of quality management, including pre-sales and after-sales service for users, the quality of products is ultimately identified and evaluated by users in the process of use......

online message