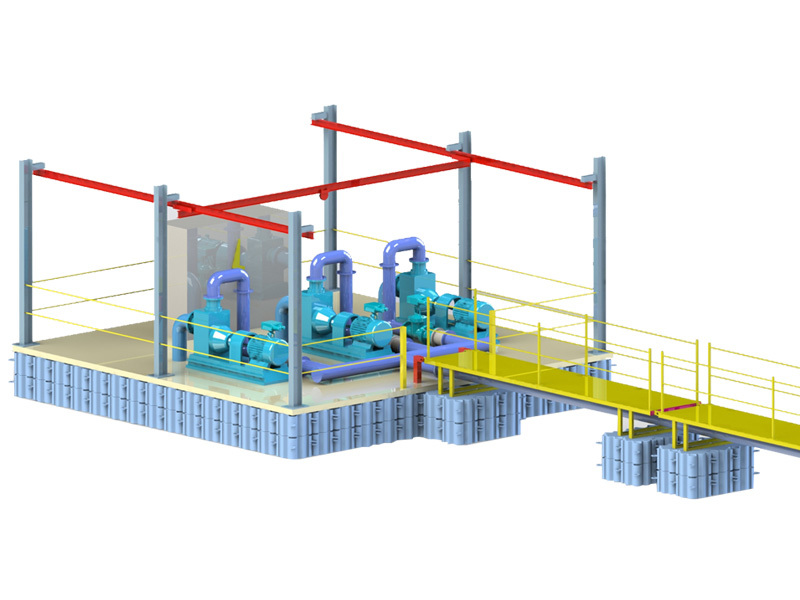

DYMK floating platform water and sand pumping station

Category:

Process pump

Hotline:

Product Overview

Adopt high molecular weight and high density HDPE module as the carrier of the system platform, build steel equipment installation platform on it to form a floating water intake and sand extraction system, which is not subject to changes in water level, river bed movement and high mountains and other geographical environment restrictions and can efficiently transport media.

Structure composition

Floating water intake and sand pumping station is composed of float, platform frame, water intake pump set, valve and outlet pipe, lifting maintenance device, lighting system, local control cabinet, PLC remote intelligent control system, anchoring system, trestle drainage pipe system, etc. The platform is equipped with a closed simple steel structure room.

Product Features

Easy assembly, fast, light equipment, short construction cycle; Water intake of equipment is balanced, safe and stable; The modular structure is convenient for transportation and easy to install. The product has strong practicability, anti-ultraviolet, anti-cold and anti-freezing, anti-oxidation, high temperature, anti-static, acid-alkali corrosion resistance, no pollution, no damage to the environment.

Scope of Application

For rivers and lakes, reservoirs, tailings ponds, drought water intake, farmland irrigation and other domestic and industrial water diversion. The product has advanced technology, wide range of adaptation and obvious economic benefits.

Comparative Advantage 1

| floating water and sand platform | Steel Marine water intake platform |

| 01 | 01 Water supply limited by water level |

| 02 No complex underwater structures | 02 High infrastructure investment |

| 03 Short construction period, fast results, less investment | 03 Poor intake water quality |

Comparison of Modular floating platforms and steel pontoons

|

Modular floating platform |

Steel float |

|

|

Carrier material |

Float material uses strong HDPE (high molecular weight high-density polyethylene), adding a variety of chemical additives. |

Using steel for anticorrosive coating treatment, carbon steel in a humid environment, prone to chemical corrosion, service life is easily affected by the medium. |

|

Security |

The size of the carrier monomer (500*500*400mm) is small, and single damage does not pose a risk to the platform structure; |

The use of segmental box-type structure (3000*2000*1000mm or more), a single cabin damage may cause greater risk |

|

Installation |

Single carrier small size, light weight, can be arbitrarily combined according to need, short installation cycle, low cost |

Assembly requires equipment, high installation cost, |

|

Production cycle |

The buoy is prefabricated once, and the production cycle is fast; |

Floating body welding molding, welding requirements are very strict, the production cycle is long; |

|

Transportation and installation |

Regular shape, easy to load and transport. Light weight (about 7kg), easy installation, site installation requirements are relatively low. |

Box-type structure, large shape, high transportation cost, site installation and hoisting requirements, the site installation environment requirements are relatively high. |

|

Operating cost |

No need to report to the government every year special review, low cost. Carrier 15 years maintenance free. |

Special operations require production license and classification society certification, and the production cost is high. Need regular inspection and maintenance. |

Technical Features and trends

♦ Selection design of water supply system from pump

♦ Short construction period, less investment, fast results

♦ Electrical control system

♦ The float platform is made of polymer environmental protection materials, stable quality, low cost, long service life

♦ Buoy service life 4 times longer than ordinary buoy

♦ Can be adjusted according to the complex transport road conditions, installation does not need a large crane

♦ Greater flexibility and no complex underwater construction

Keywords:

DYMK floating platform water and sand pumping station

Previous

Previous

Why choose us

R&D Center

The processing workshop covers an area of approximately 5724 square meters and has various large-scale equipment such as ordinary lathes, vertical lathes, grinders, boring machines, and gantry boring and milling machines. Capable of turning parts with a rotating diameter of up to 4.5 meters and adding

R&D personnel

Technical support from the company. With technical support from professional energy-saving pump research institutes, laboratories, and strategic partners of pump manufacturers, we can design various models of products

After-Sale Service

The entire process of quality management, including pre-sales and after-sales service work for users, and the quality of products is ultimately identified and evaluated by users during use

MESSAGE