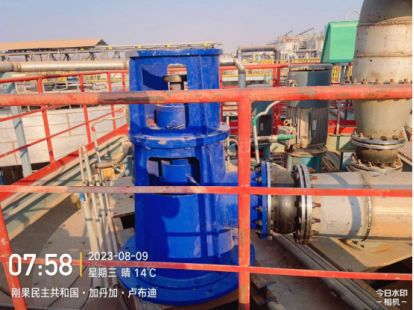

Longitudinal pump

Classification:

Product Center

Pump

Hotline:

Structural Features

- Longitudinal Shaft Design The pump shaft can be tens of meters long, connected by multiple couplings to adapt to different submergence depth requirements. The shaft body uses high-strength materials (such as stainless steel) and is equipped with guide bearings (polytetrafluoroethylene or rubber material) to reduce radial swing and ensure stable operation.

- Impeller and Pump Casing The impeller is an outward-inclined reverse rotation design, which works with the volute pump casing. Through centrifugal force, the liquid is thrown from the center of the impeller to the outer edge, achieving energy conversion. The pump casing flow path gradually expands, causing the liquid to decelerate and increase pressure, finally flowing into the discharge pipe at high pressure.

- Seals and Bearings The shaft seal uses packing seals or mechanical seals (single/double-ended) to prevent leakage; thrust bearings (dry or thin oil lubrication) bear the axial force and rotor weight, and the motor support or special bearing box provides support.

Key words:

Next Page

Why choose us

Why choose us

R & D Center

The processing workshop covers an area of about 5724 square meters, with ordinary lathes, vertical lathes, grinders, boring machines, gantry boring and milling machines and other large equipment. Turning can rotate each meter parts and add within 4.5 meters in diameter...

R & D personnel

The company's technical support. With technical support from professional energy-saving pump research institutes, laboratories, and strategic partners of pump manufacturing enterprises, it can design various types of products......

After-sales service

The whole process of quality management, including pre-sales and after-sales service for users, the quality of products is ultimately identified and evaluated by users in the process of use......

online message